Unmatched Quality of Heavy Duty Casters Manufactured in China for Global Buyers

As the demand for

durable and reliable industrial solutions

continues to rise globally,

heavy duty casters

have become an essential component for businesses looking to enhance operational efficiency. According to a recent market research report by Grand View Research, the global caster market is projected to reach

USD 5.1 billion

by 2025, driven primarily by the booming logistics and manufacturing sectors. Heavy duty casters, designed to support substantial loads while maintaining maneuverability, are at the forefront of this growth.

With China's advanced manufacturing capabilities and commitment to quality,

Chinese manufacturers

are setting new standards in producing heavy duty casters that meet international specifications.

This blog aims to delve into the intricate technical parameters of these products, showcasing how they not only fulfill but exceed

global buyer expectations,

ensuring operational excellence in various industrial applications.

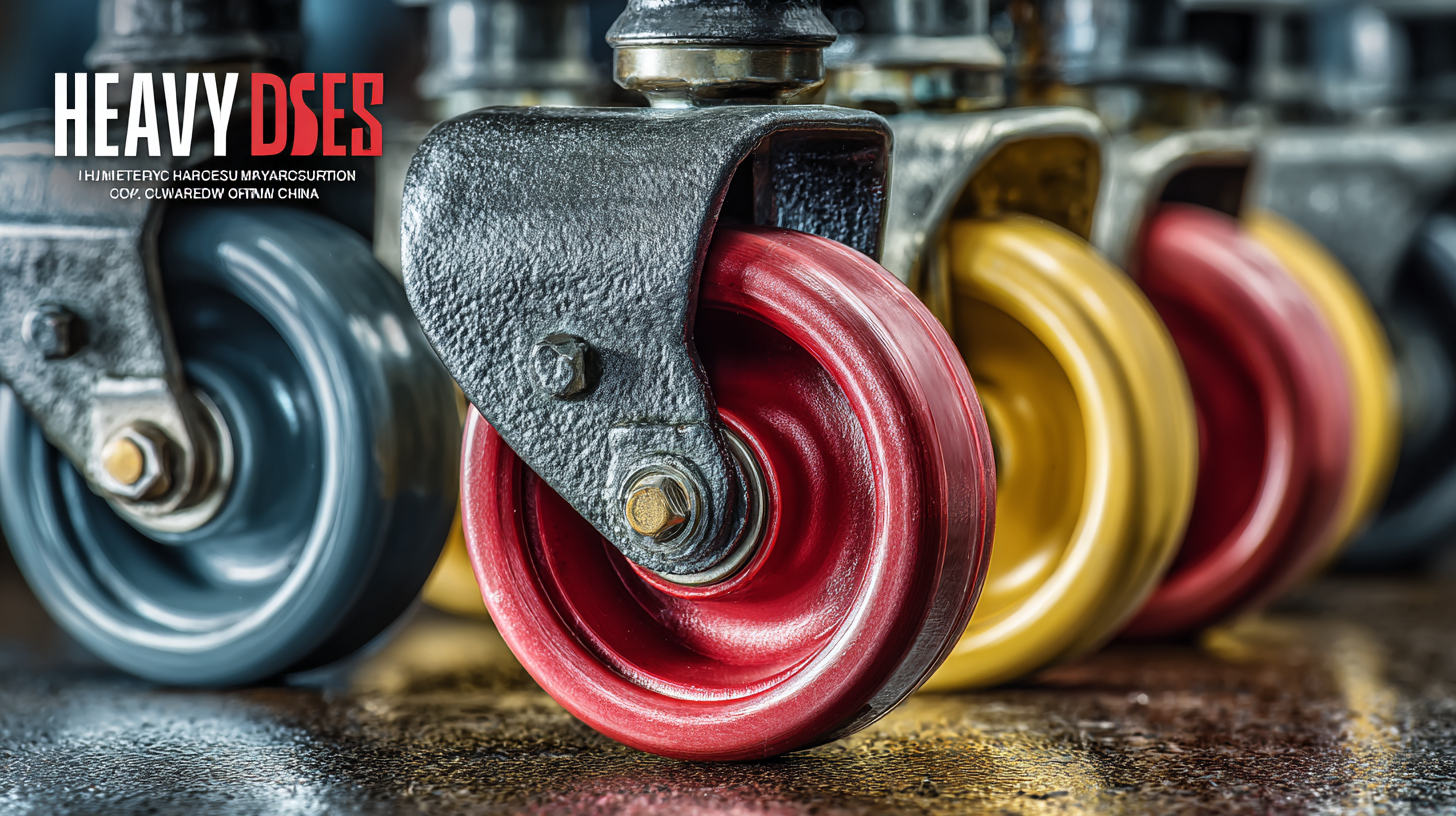

Unveiling the Superior Design of Heavy Duty Casters Made in China

Heavy-duty casters are essential components in various industries, enabling the smooth movement of heavy loads in warehouses, factories, and logistics operations. The superior design of heavy-duty casters manufactured in China not only meets but often exceeds global industry standards. According to a recent report by Grand View Research, the global caster wheels market is projected to reach $3.79 billion by 2025, with a significant portion driven by innovations in design and materials. Chinese manufacturers have leveraged advancements in technology to create casters that are not only durable but also eco-friendly, catering to the increasing demand for sustainable solutions in industrial applications.

The design quality of these heavy-duty casters can be attributed to several factors, including the use of high-grade materials such as thermoplastics and metals that enhance load-bearing capacity and durability. Furthermore, many Chinese manufacturers focus on detailed engineering processes, ensuring that each caster is tested under stringent conditions. A study from MarketsandMarkets indicates that performance improvements in caster wheels can lead to a 20% increase in operational efficiency, emphasizing the importance of selecting quality products. As global buyers continue to seek reliable solutions, the unmatched quality and innovative designs of heavy-duty casters made in China position them as a preferred choice in the international market.

Unmatched Quality of Heavy Duty Casters Manufactured in China for Global Buyers

| Model |

Load Capacity (lbs) |

Wheel Material |

Wheel Diameter (inches) |

Swivel Radius (inches) |

Mounting Height (inches) |

| HC-1000 |

1000 |

Polyurethane |

5 |

4 |

6 |

| HC-2000 |

2000 |

Nylon |

6 |

5 |

7 |

| HC-2500 |

2500 |

Rubber |

8 |

6 |

8 |

| HC-3000 |

3000 |

Polyurethane |

10 |

7 |

9 |

Understanding Industry Standards for Heavy Duty Caster Production

The heavy-duty caster industry is increasingly being shaped by global standards and innovative technologies, particularly among manufacturers based in China. Understanding the intricacies of industry standards is crucial for global buyers seeking top-notch quality and performance in their caster products. As the demand for heavy-duty solutions rises, manufacturers must adhere to stringent quality benchmarks while embracing advancements in design and materials. For instance, the recent acquisition of a caster manufacturer in Southern California underscores the ongoing consolidation of expertise and the sharing of best practices, which ultimately enhances product reliability.

Moreover, companies are exploring new methodologies to improve their offerings. Innovations such as omni-directional motor-powered systems illustrate a commitment to enhancing functionality and ease of use, which are vital in industries relying heavily on efficient material handling. This dedication to innovation not only meets current industry standards but also sets the stage for future advancements, ensuring that heavy-duty casters manufactured in China remain competitive on a global scale.

Through continuous investment in technology and adherence to evolving standards, manufacturers can guarantee unmatched quality and performance, thereby solidifying their market position and fulfilling the diverse needs of their international clientele.

Key Materials Used in High-Quality Heavy Duty Casters

When it comes to high-quality heavy duty casters, the materials used in their manufacturing play a crucial role in their performance and durability. Manufacturers in China are leading the way by utilizing advanced materials that cater to the demands of global buyers. For instance, premium-grade steel and reinforced nylon are common choices that provide the necessary strength and resilience, ensuring these casters can handle substantial weights and endure various working conditions.

In addition to steel and nylon, the incorporation of innovative rubber compounds enhances the functionality of heavy duty casters. This not only improves traction and minimizes wear on various surfaces but also helps absorb shocks and vibrations during movement. With a focus on superior materials, these casters stand out in several applications, from industrial machinery to heavy furniture, making them an essential component for efficient material handling and logistics. The combination of robust materials and meticulous engineering guarantees that buyers receive products that not only meet but exceed their expectations in quality and performance.

Global Market Trends for Heavy Duty Casters and Chinese Manufacturers

The global market for heavy-duty casters has seen significant growth, driven by the increasing demand from various industries such as manufacturing, logistics, and healthcare. According to a recent report by Market Research Future, the heavy-duty caster market is projected to reach USD 3.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.2%. This growth is largely attributed to the rise in e-commerce and the need for efficient material handling solutions, with heavy-duty casters playing a crucial role in enhancing mobility and load management.

Chinese manufacturers have emerged as key players in this burgeoning market, offering unmatched quality and cost efficiency. Data from the China Caster Industry Association indicates that over 60% of the world's heavy-duty casters are produced in China, benefiting from advanced manufacturing techniques and strict quality control measures. Furthermore, the global buyer’s shift towards sourcing from China is bolstered by competitive pricing and the ability to meet large-scale orders without compromising quality, making Chinese casters an attractive option for international markets. As industries continue to modernize their operations, the role of high-quality heavy-duty casters from China will undoubtedly become more prominent.

Advantages of Sourcing Heavy Duty Casters from China for International Buyers

Sourcing heavy-duty casters from China offers international buyers numerous advantages that significantly enhance cost-effectiveness and quality assurance. According to a report by Grand View Research, the global caster market is expected to reach $4.6 billion by 2025, with China being one of the leading manufacturers. This dominance can be attributed to the country's advanced manufacturing capabilities, which include the use of cutting-edge technology and materials that meet international standards.

Moreover, China's established supply chain and economies of scale allow manufacturers to produce heavy-duty casters at competitive prices. The ability to source high-quality products at a lower cost is particularly beneficial for international buyers looking to maximize their profit margins. Industry analyses have shown that buyers can save up to 30% on costs by sourcing directly from Chinese manufacturers compared to local suppliers in western countries. Additionally, Chinese manufacturers often provide a diverse range of heavy-duty caster designs, suitable for various applications in industries such as logistics, automotive, and healthcare, ensuring that buyers can find tailored solutions for their specific needs.