A button head grease fitting is essential in machinery maintenance. This small but crucial component allows for easy lubrication of moving parts. According to a report by the National Lubricating Grease Institute, proper lubrication can extend the life of equipment by 50%. This highlights the importance of grease fittings in ensuring operational efficiency.

These fittings are designed for convenience. Their button head shape allows a grease gun to easily connect and apply lubricant. In industrial settings, machinery failures often lead to down time. Downtime can cost companies thousands of dollars each hour. Thus, a button head grease fitting plays a vital role in preventing such losses.

However, not all users utilize greasing systems effectively. Some may overlook the need for regular maintenance. Reports indicate that nearly 30% of machinery failures result from inadequate lubrication. This underlines the need for proper education on the significance of the button head grease fitting. Regular checks and proper installation are key to maximizing their benefits.

A Button Head Grease Fitting is a specialized component used in lubrication systems. Its innovative design allows for easy grease application in tight spaces. The button head shape enables tools to connect effortlessly, promoting efficient maintenance. Industries that heavily rely on machinery often utilize this fitting for timely lubrication.

Research indicates that proper lubrication can enhance equipment lifespan by up to 40%. However, many operators neglect maintenance, leading to costly repairs. A Button Head Grease Fitting addresses this issue by simplifying the lubrication process. It's crucial for operators to regularly check these fittings. A worn-out grease fitting not only hinders performance but can also lead to equipment failure.

While these fittings are beneficial, they aren't foolproof. Users must remain vigilant about their condition. Sometimes, grease can harden or clump inside. This buildup can cause blockages, impacting machinery efficiency. Regular inspections will help identify potential issues before they escalate. Emphasizing proactive maintenance can save significant downtime in production.

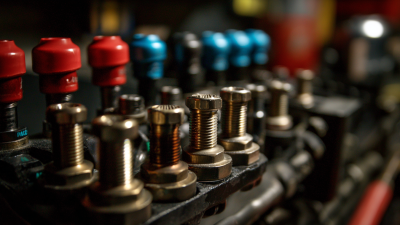

Button head grease fittings are essential components in lubrication systems. They help in maintaining machinery and extending its lifespan. These fittings have a rounded head, which allows easy access for grease guns. Their design ensures a reliable seal, preventing dirt and moisture intrusion.

Key features of button head grease fittings include their durability and simplicity. They often come in various sizes to fit different applications. The rounded shape makes it easier to align the grease gun, reducing mess during operation. Some models even have a built-in check valve, which prevents grease from leaking out.

Tips: Choose the right size for your specific equipment. A common mistake is using the wrong fitting size, which can lead to ineffective lubrication. Regularly inspect your fittings for wear or damage. Addressing minor issues early can prevent major problems later.

Button head grease fittings are widely used in various mechanical applications. Their design allows for easy access to lubricate moving parts. This feature helps to reduce friction and extend the life of machinery. Commonly, these fittings are found in automotive and industrial equipment. They offer convenience in tight spaces where traditional fittings may not fit.

One prevalent application is in automotive assembly lines. Here, button head grease fittings allow workers to quickly apply grease to critical components. Equipment like tractors and construction machinery also relies on these fittings. They help maintain performance by ensuring consistent lubrication to swivel joints and pivot points. However, users may overlook these fittings during maintenance. Ensuring they are operational is crucial for performance.

Button head grease fittings can also be found in household appliances. For example, garage door mechanisms use these fittings for lubrication. Without proper care, the grease can harden and cause jams. This issue highlights the importance of regular inspections. Users should reflect on their maintenance routines to avoid these pitfalls.

Button head grease fittings are essential components in various machinery. Proper installation is crucial for optimal performance. Start by selecting the right grease fitting for your application. It should fit snugly with the installation point. Make sure the fitting is clean before proceeding. Avoid using excessive force when inserting it. This can damage the threads or misalign the fitting.

Maintenance is just as important. Regularly check the fittings for wear and tear. Look for signs of leaking or blockage. If you notice any issues, it’s time for a replacement. Cleaning the grease fitting regularly helps prevent dirt buildup. Ensure you apply the correct lubricant type as specified for your machinery. Remember, improper lubrication can lead to serious issues down the line. Regular maintenance can save you from costly repairs.

Keeping track of installation dates is beneficial. It helps in scheduling timely maintenance. Utilizing a maintenance log can keep things organized. If you find your grease fittings working poorly, evaluate your installation approach. Sometimes a simple adjustment can make a big difference. Stay proactive, and don’t overlook the small details. They often lead to the best outcomes.

Button head grease fittings play a vital role in machinery maintenance. These fittings allow easy lubrication access to various components. Regular lubrication can extend the life of machines. With their unique design, button head fittings offer a secure connection that reduces the risk of leaks. This design promotes efficient grease distribution, ensuring all moving parts are adequately serviced.

Using button head grease fittings has several benefits. They provide an efficient way to maintain machinery. The ease of access encourages regular maintenance, which many operators often overlook. This can lead to mechanical failure. Proper lubrication prevents wear and tear, which can be expensive to repair. Moreover, the visual cue from the button head ensures you don’t miss connections during maintenance checks. However, some users struggle with tight spaces, making access challenging at times. This can lead to inconsistencies in lubrication practices, something that should be addressed carefully.