The importance of maintaining machinery longevity and operational efficiency cannot be overstated, especially in industries relying heavily on mechanical components. As equipment experiences wear and tear, the effective application of lubrication is crucial for minimizing friction and maximizing performance. In this regard, the button head grease fitting emerges as an essential component in ensuring seamless lubrication across various systems. According to a recent report by the Machinery Maintenance Magazine, over 30% of equipment failures can be attributed to inadequate lubrication practices. This statistic highlights the critical role that proper grease fittings, such as the button head type, play in prolonging the life of machinery.

Looking ahead to 2025 and beyond, advancements in lubricating technologies will likely enhance the efficacy of button head grease fittings, making them even more pivotal in maintenance regimes. Research indicates that the global market for lubrication products is projected to grow at a CAGR of 3.5%, driven by the increasing adoption of automated lubrication systems across various sectors. As industries evolve, the adaptability and reliability of button head grease fittings will become integral not only to equipment efficiency but also to reducing operational costs and downtime. This top guide delves into the intricacies of button head grease fittings, offering insights into their advantages, applications, and future trends in lubrication technology.

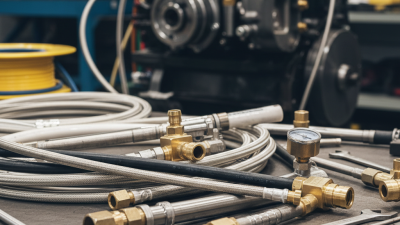

Button head grease fittings are essential components in various mechanical systems, providing a reliable means for lubrication. These fittings feature a rounded, button-like head that allows for easy access and application of grease, ensuring that moving parts operate smoothly and efficiently. Designed to accommodate standard grease guns, button head fittings help to minimize the risk of contamination, making them an ideal choice for both light and heavy machinery.

The versatility of button head grease fittings extends across multiple industries, from automotive to agricultural applications. Their design not only facilitates quick and easy lubrication but also enhances the durability of the components they service. By reducing friction and wear between moving parts, these fittings play a crucial role in extending the lifespan of machines, thereby promoting better performance and reducing maintenance costs. Understanding how to properly use and maintain button head grease fittings is vital for anyone involved in equipment care or machinery operation, as it can lead to significant operational efficiency gains.

Button head grease fittings have become an increasingly popular choice in maintenance and machinery lubrication, especially as we move into 2025 and beyond. Their unique design allows for efficient greasing, minimizing the risk of leakage and ensuring optimal performance in mechanical applications. The key features of button head grease fittings include an ergonomic design that facilitates easy access, even in tight spaces, and robust materials that withstand harsh environmental conditions. This makes them ideal for heavy machinery and equipment exposed to dirt, moisture, and extreme temperatures.

One of the primary benefits of using button head grease fittings is the improved lubrication flow, which promotes better equipment longevity and reliability. These fittings enable users to apply grease precisely where it is needed, reducing waste and ensuring that components remain properly lubricated. Additionally, they reduce the risk of contaminants entering the lubrication system, further enhancing the efficiency of the machinery.

**Tip:** When selecting button head grease fittings, consider the size and thread type to ensure compatibility with your equipment. Regularly inspect the fittings for wear and replace them as needed to maintain optimal performance. Another useful tip is to keep a grease gun handy and practice a consistent maintenance schedule to avoid potential downtime in operations.

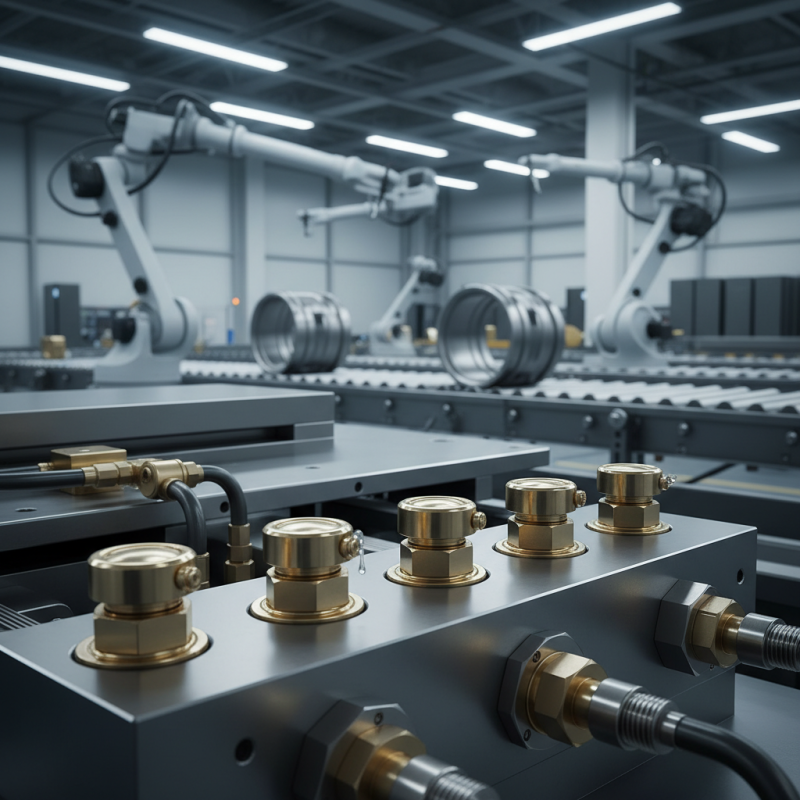

Button head grease fittings are increasingly becoming essential components across various industries, owing to their efficiency in lubrication applications. In the automotive sector, for instance, they are commonly used in maintenance tasks to ensure smooth functioning of critical moving parts. A recent industry report from the International Society of Automotive Engineers (SAE) highlighted that proper lubrication can enhance the lifespan of vehicle components by up to 30%, making these fittings invaluable for regular service.

In manufacturing and heavy machinery, button head grease fittings also serve a crucial role. They facilitate efficient grease distribution in machinery that operates under heavy loads and extreme conditions. According to a study conducted by the Machinery Lubrication Association, proper lubrication practices can reduce machine downtime by 25%, contributing significantly to operational efficiency. This suggests that the adoption of button head fittings in these environments can lead to considerable cost savings and productivity enhancements.

**Tips:** When selecting button head grease fittings, ensure they meet the specific pressure and temperature requirements of your application. Regular inspection and maintenance can further improve the performance and lifespan of these fittings, ensuring optimal lubrication despite the demanding conditions often faced in industrial settings. Additionally, using high-quality grease formulated for your machinery's specifications can enhance the effectiveness of these fittings, promoting seamless operation.

This chart illustrates the various applications of Button Head Grease Fittings across different industries, highlighting their significance in terms of percentage usage for 2025 and beyond.

Maintaining grease fittings is essential for ensuring optimal performance and longevity in machinery and equipment. Regular inspection is a vital step in this process. Operators should check for any signs of wear, leakage, or blockages that could impede the flow of grease. Ensuring that the fittings are clean and free from contaminants before applying grease can prevent damage and improve lubrication efficiency. It’s advisable to use a brush or compressed air to clear out any debris that may accumulate around the fittings.

Another key maintenance tip is to adhere to a consistent greasing schedule aligned with the manufacturer's recommendations. Over-greasing can lead to excessive pressure within the system, potentially causing seals to rupture or fittings to fail. Conversely, under-greasing can result in insufficient lubrication, leading to increased friction and wear on moving parts. Utilizing a grease gun with a pressure gauge can help achieve the optimal amount of grease, ensuring that each fitting is adequately serviced while preventing common maintenance pitfalls. Regular monitoring of the grease quality is also crucial; contaminants should be addressed promptly to maintain the integrity of the lubrication system.

As we move into 2025 and beyond, the landscape of button head grease fitting technology is set to undergo significant transformations. One of the most notable trends is the integration of advanced materials that enhance the durability and efficiency of these fittings. Manufacturers are increasingly turning to composite materials that offer better resistance to corrosion and wear, ultimately leading to longer service life and reduced maintenance costs. This focus on longevity aligns with broader sustainability initiatives, as companies seek to minimize waste and environmental impact by creating products that last longer.

Additionally, the rise of smart technology is poised to revolutionize how button head grease fittings are monitored and maintained. Innovations such as smart sensors integrated into the fittings can provide real-time data on lubrication levels, pressure, and overall system health. This enables predictive maintenance strategies, allowing operators to address potential issues before they escalate into costly failures. As industries continue to embrace the Internet of Things (IoT), the adoption of these smart grease fittings will likely become the norm, enhancing operational efficiency and safety across various applications.

| Trend | Description | Expected Impact | Adoption Rate (%) | Innovation Timeline |

|---|---|---|---|---|

| Smart Grease Fittings | Integration of IoT technologies for real-time monitoring. | Improved maintenance schedules and reduced downtime. | 60% | 2025-2026 |

| Eco-Friendly Materials | Use of biodegradable greases and recycled plastics. | Reduction in environmental impact and compliance with regulations. | 40% | 2024-2025 |

| Enhanced Durability | Developments in materials to resist harsh operating conditions. | Increased lifespan of fittings and reduced costs. | 50% | 2023-2024 |

| Automation Integration | Fittings designed for automated lubrication systems. | Boosted efficiency in lubrication processes. | 70% | 2025-2027 |

| Data Analytics | Utilization of big data to optimize lubrication patterns. | Reduced wear and tear through informed decision-making. | 65% | 2025-2028 |