In the world of industrial piping, the choice of valves plays a crucial role. Among various types, the "4 inch gate valve" stands out for its reliability and efficiency. John Smith, a piping industry expert, noted, "Choosing the right valve can prevent significant operational issues." His insight emphasizes the importance of careful selection.

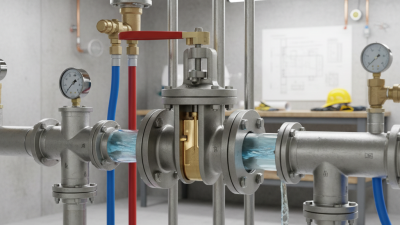

The 4 inch gate valve is widely used in various applications. It provides a tight seal and allows for smooth flow control. These valves are designed for high-pressure systems, making them suitable for harsh environments. Observations indicate that many industries prefer them over others for their durability. However, not all 4 inch gate valves are equal. It's essential to assess quality and performance.

Still, some may overlook maintenance aspects. Regular checks can prevent issues that compromise functionality. Relying solely on specifications might lead to unexpected challenges. The 4 inch gate valve is a fantastic option, but selecting the right model requires thorough consideration. Ultimately, understanding your needs is paramount for successful piping operations.

When considering piping needs, understanding the basics of

4 inch gate valves is essential. These valves are designed to control flow through a piping system.

They work by lifting a gate out of the path of the fluid. Their simple construction ensures durability and reliability.

However, their effectiveness is strongly influenced by proper installation.

4 inch gate valves are often chosen for high-flow applications.

They can quickly open and close, minimizing interruptions. But improper use can lead to leaks or failures.

Some may overlook the importance of regular maintenance.

Routine checks can prevent costly repairs down the line. It's crucial to evaluate the surrounding conditions where the valve operates.

Installation height and alignment play a vital role. If these aren’t addressed, the gate could malfunction.

Some users may forget to account for thermal expansion in piping systems.

Ignoring this can lead to undue stress on the valve. A thorough understanding of gate valves promotes better decision-making and smoother operations.

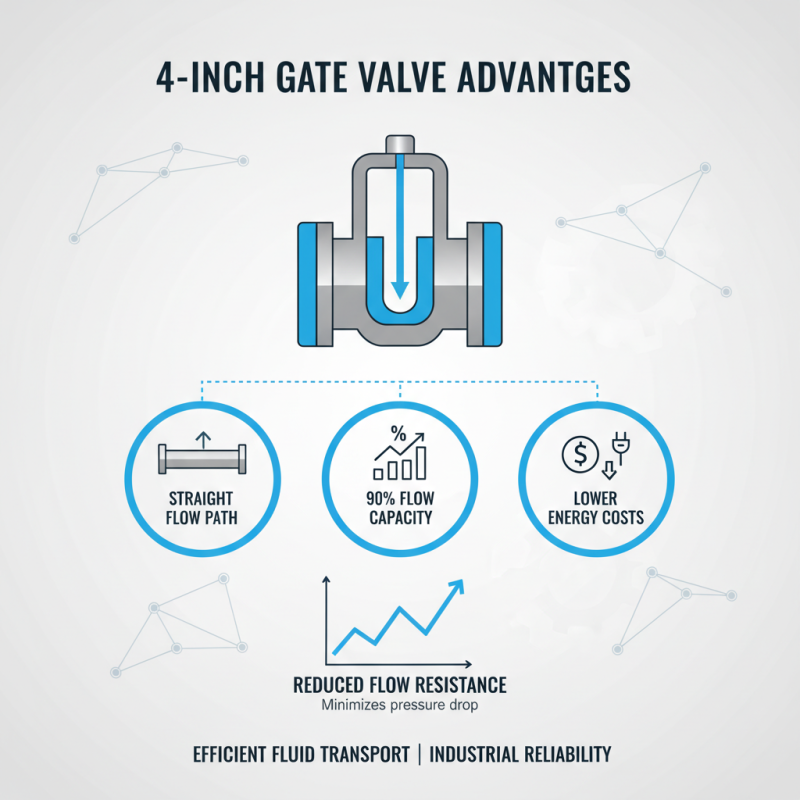

A 4 inch gate valve is often chosen for its significant advantages in piping systems. The primary benefit lies in its ability to provide a straight flow path. This design minimizes flow resistance, making it efficient for high-volume fluid transport. According to industry reports, a gate valve can achieve up to 90% flow capacity compared to other valve types. This increase can result in lower energy costs over time for operations.

Another key advantage is durability. 4 inch gate valves are designed for long-lasting performance. They can withstand high pressures, and extreme temperatures, and resist corrosive materials. This durability reduces maintenance costs, as valves don’t need frequent replacements. Studies indicate that systems using these valves have a 20% lower downtime percentage, aiding consistent operations.

**Tip:** Always consider the valve's material. Opting for the right material can further enhance durability.

However, there are considerations. Proper installation is crucial. Incorrect installation can lead to failures, causing leakages. It is essential to assess the specific requirements of your piping system. This may involve recalibrating flow dynamics or pressure limits, as different environments exert various stresses on valves.

**Tip:** Regular inspections can catch issues early. Keep an eye on performance to avoid larger problems down the road.

When considering piping needs, the 4-inch gate valve stands out in various industries. These valves are often used in water supply systems. Their primary function is to start or stop the flow of liquids. In municipal applications, they help manage water distribution. They enable smooth operations when installed in pipelines.

Another significant area is in oil and gas. A 4-inch gate valve can control high-pressure systems. These valves are reliable under extreme conditions. However, improper maintenance can lead to failures. Regular checks are crucial to prevent unexpected issues.

In HVAC systems, they regulate airflow and fluid flow. They maintain temperature control effectively. Industries often adopt gate valves due to their simple design. Yet, attention to detail is essential. Overlooking small faults can result in bigger problems later.

When considering a 4-inch gate valve, installation and maintenance are crucial factors. These valves are primarily used in water supply and wastewater systems. Proper installation prevents leaks and ensures a longer lifespan. Experts recommend aligning the valve with the pipeline. Misalignment can lead to stress and premature failure, impacting system efficiency.

Maintenance of 4-inch gate valves is equally important. Regular checks can prevent significant issues. According to industry reports, nearly 15% of operational failures stem from poor upkeep. Inspect seals and hoses routinely. Wear and tear can compromise functionality. Lubricate the stem when necessary; it ensures smooth operation and reduces friction.

While gate valves are durable, they require careful handling. A study found that improper operation can decrease efficiency by up to 20%. Operators should be trained and aware of best practices. It’s easy to overlook small details, but neglect can lead to larger problems down the line.

When considering piping solutions, a 4-inch gate valve offers unique advantages. Unlike ball valves, gate valves excel in areas where full flow is critical. Their design allows for minimal pressure drop, which is essential in large systems. A 4-inch size balances flow and control effectively, catering to both residential and industrial needs.

However, gate valves have their downsides. They are not ideal for throttling flow. If precise control is necessary, other valves might be more suitable. For example, globe valves allow finer adjustments. While gate valves can be easier to operate, they require complete opening or closing. This might not suit all applications, especially in dynamic flowing environments.

In terms of durability, 4-inch gate valves often outlast many alternatives. They can withstand high pressure and temperature. Still, the maintenance of these valves is crucial. Regular checks can prevent leaks and failures. Users need to weigh these factors carefully. Balancing cost, function, and maintenance can be tricky. Choose wisely based on your piping needs.

| Valve Type | Size | Material | Pressure Rating (psi) | Application |

|---|---|---|---|---|

| Gate Valve | 4 Inch | Cast Iron | 150 | Water Supply |

| Ball Valve | 4 Inch | PVC | 200 | Chemical Processing |

| Globe Valve | 4 Inch | Stainless Steel | 300 | Flow Regulation |

| Butterfly Valve | 4 Inch | Aluminum | 150 | HVAC Systems |

| Check Valve | 4 Inch | Bronze | 150 | Backflow Prevention |