When it comes to maintaining machinery, choosing the right components is crucial. One effective solution is grease line tubing and fittings. These parts are designed to ensure efficient lubrication, making machinery run smoother and last longer.

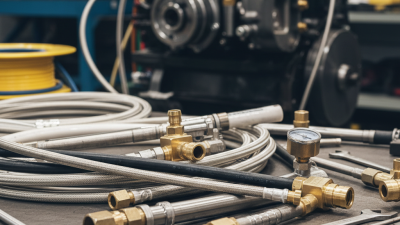

Grease line tubing and fittings come in various materials and sizes. Selecting the wrong type can lead to ineffective lubrication. Inadequate lubrication can cause wear and tear, affecting performance. It's essential to consider compatibility with your machinery. This choice may require careful thought and a bit of research.

Additionally, installation challenges can arise. Not everyone will have the expertise required. However, understanding the advantages of grease line tubing and fittings can make a difference. They offer reliability and durability that can enhance machine performance. Choosing wisely may eliminate costly repairs in the long run.

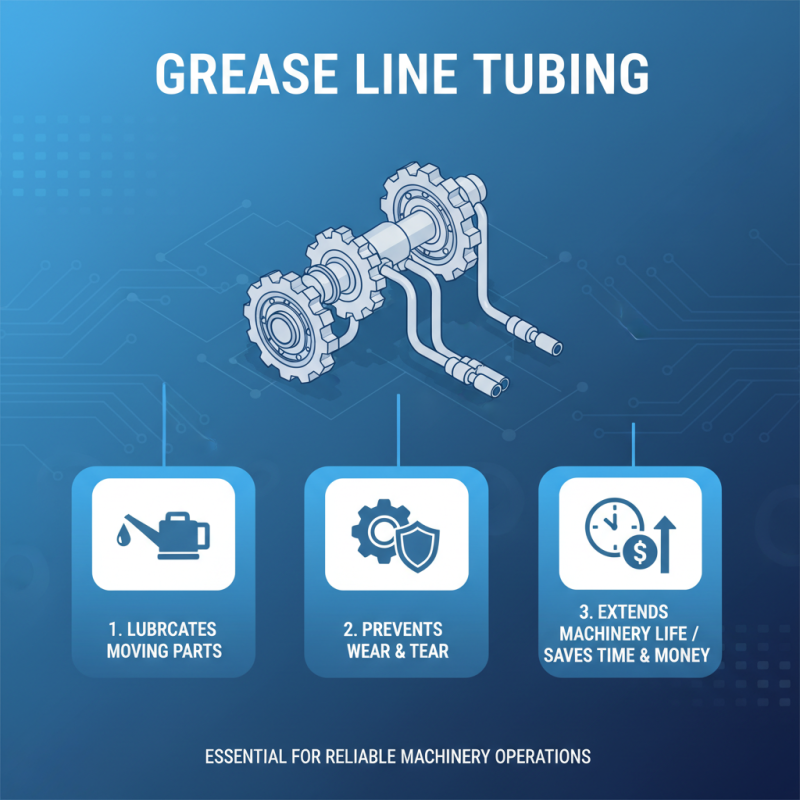

Grease line tubing is essential in machinery operations. It helps lubricate various moving parts. This prevents wear and tear, extending the machinery's life. Understanding its function can save time and money in the long run.

Grease line tubing is typically made from durable materials. It withstands pressure and temperature changes. These factors are critical in machinery where efficiency is key. When choosing fittings, ensure compatibility. Different machinery may require specific sizes or types.

**Tip:** Regular maintenance checks are vital. Inspect tubing for any cracks or wear. Replace damaged parts promptly.

Choosing the right fittings is equally important. Leaky connections can lead to failures. Always tighten joints properly to avoid accidents.

**Tip:** Keep a record of your machinery's lubrication history. This aids in identifying patterns and potential issues. Consider implementing a routine check-up schedule to catch problems early.

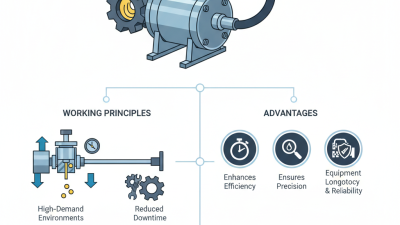

Grease line fittings offer several key benefits for machinery. First, they ensure efficient lubrication. Proper lubrication reduces friction. This can extend the life of your equipment. Less wear means fewer repairs. It saves time and costs in the long run.

Another important aspect is ease of maintenance. Grease fittings allow quick access to lubrication points. This simple feature can make routine maintenance more manageable. Workers can spend less time on these tasks, which can improve productivity. In addition, it lowers the risk of neglecting lubrication.

Despite these advantages, it’s essential not to overlook the importance of regular checks. Without scheduled maintenance, any system can fail. Grease containers can become clogged, leading to issues. Keeping a consistent maintenance schedule is vital. This ensures that grease flows smoothly through the system.

When selecting grease line tubing, several factors come into play. The material of the tubing is crucial. High-quality materials ensure durability and resistance to wear. Look for tubing that can withstand pressure and temperature changes. It's essential to consider the compatibility of the tubing with the grease type used. Mismatched materials can lead to leaks and failures.

Another vital factor is the size and length of the tubing. Too short or too long can cause issues during installation. Accurate measurements will help in avoiding unnecessary frustrations. Proper fittings are equally important. They should ensure a tight seal to prevent leaks. Don’t overlook this aspect, as a faulty fitting can lead to expensive repairs.

Finally, consider the environmental conditions where the machinery operates. Harsh conditions may require specialized tubing. Reflect on your specific needs. Research and seek expert advice if necessary. It’s better to take time upfront than to deal with problems later on.

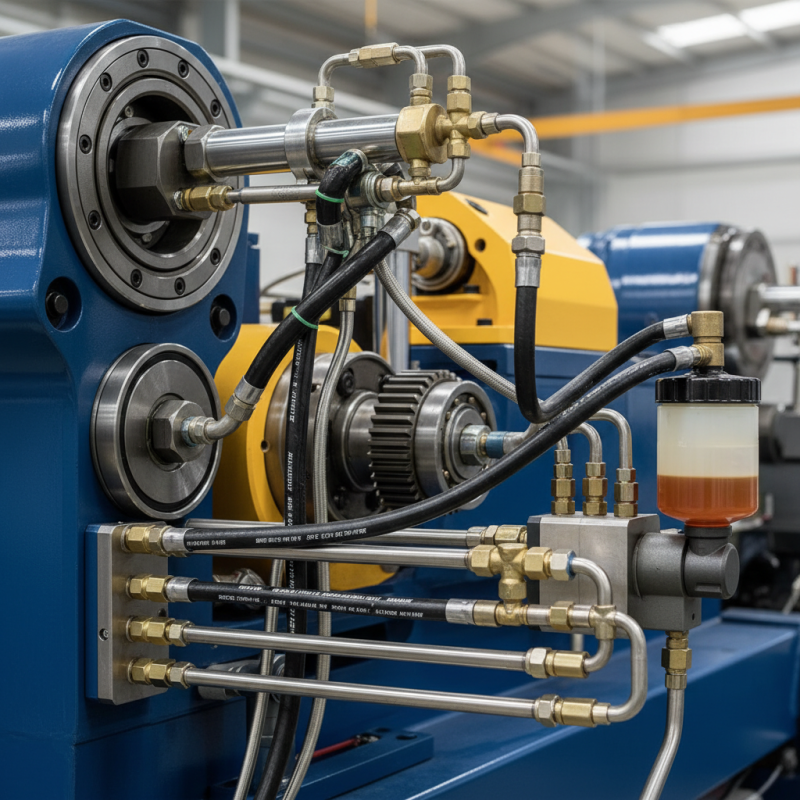

Maintaining grease line tubing and fittings is essential for optimal machinery performance. Regular inspections can help identify early signs of wear or damage. Look for cracks or kinks in the tubing. These issues can lead to grease leakage, which affects the lubrication of moving parts. If you notice any irregularities, take action immediately.

Cleaning is another vital maintenance step. Use a suitable cleaning agent to remove contaminants from fittings. Old grease can accumulate and cause blockages. For efficient lubrication, ensure that the fittings are free of any debris. It’s a good practice to replace worn-out parts promptly. This prevents potential machinery downtime.

Don’t overlook the connection points. Often, they are the weakest link. Tighten them regularly to prevent any leaks. Always have some spare parts available. This can minimize the disruption when repairs are needed. Maintenance requires diligence and a proactive approach. Remember, a small oversight today can lead to bigger issues down the road.

| Dimension | Material | Temperature Range | Pressure Rating | Typical Applications |

|---|---|---|---|---|

| 1/4 inch | Steel | -20°F to 250°F | 3000 PSI | Industrial Machinery |

| 3/8 inch | Stainless Steel | -40°F to 300°F | 4000 PSI | Automotive Applications |

| 1/2 inch | PVC | 32°F to 140°F | 1500 PSI | Agricultural Machinery |

| 5/8 inch | Rubber | -10°F to 180°F | 2000 PSI | Construction Equipment |

When selecting grease line tubing and fittings, material choice is crucial. Different materials offer various benefits and designs. Commonly used materials include steel, rubber, and plastic. Each has unique properties that suit different applications.

Steel tubing is durable and offers high resistance to pressure. It is ideal for heavy machinery and environments where wear is a concern. However, it is susceptible to rust. Regular maintenance is key.

Rubber is flexible and can withstand various temperatures. It's great for dynamic applications. But it may degrade faster than metal in certain conditions. Monitor it closely for signs of wear.

Plastic fittings are lightweight and corrosion-resistant. They are easier to install and replace. However, they may not hold up as well under extreme pressure. Consider your specific needs before opting for plastic.

Tips: Always evaluate the environment where the tubing will be used. Look for potential physical wear points. Regular inspections will save costs in the long run. Choose based on long-term performance rather than initial cost alone.