Choosing the right 6 inch gate valve for your plumbing needs is a crucial decision that can significantly impact the efficiency and reliability of your water distribution system. According to a recent report by the International Plumbing and Mechanical Officials (IPMO), the demand for 6 inch gate valves in industrial and residential applications has increased by over 15% in the last five years, underscoring the importance of selecting the appropriate valve type for various plumbing infrastructures.

Industry expert Dr. Emily Carter, a renowned hydraulic engineer, emphasizes the critical nature of this choice, stating, "The right 6 inch gate valve not only ensures optimal flow control but also extends the lifespan of your plumbing system." With various materials, operating pressures, and design specifications available, understanding the specific requirements of your project can help you navigate the complexities of valve selection.

This introductory overview aims to guide you through the factors to consider when choosing a 6 inch gate valve, ensuring that you make an informed decision tailored to your plumbing application, ultimately enhancing performance and sustainability while minimizing maintenance and operational costs.

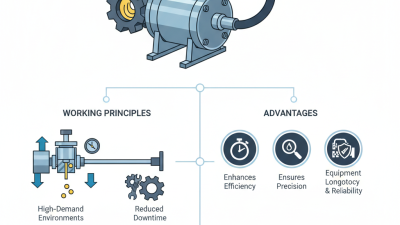

When it comes to plumbing, understanding the basics of a 6-inch gate valve is crucial for making informed decisions. A gate valve is designed to allow or restrict fluid flow in a piping system, making it an essential component for controlling water supply. Typically used in larger plumbing applications, the 6-inch gate valve operates with a sliding gate mechanism that raises or lowers to open or close the flow. This design is favored for its ability to minimize pressure loss and fluid turbulence when fully opened, making it suitable for both residential and industrial uses.

In addition to functionality, selecting the right 6-inch gate valve requires consideration of various factors, including material composition, pressure rating, and installation requirements. Common materials include cast iron, brass, and stainless steel, each offering different levels of durability and resistance to corrosion. It's also important to assess the pressure ratings and temperature specifications to ensure compatibility with your plumbing system. Finally, installation space, orientation (horizontal or vertical), and maintenance accessibility should be weighed to avoid complications in future repairs or adjustments.

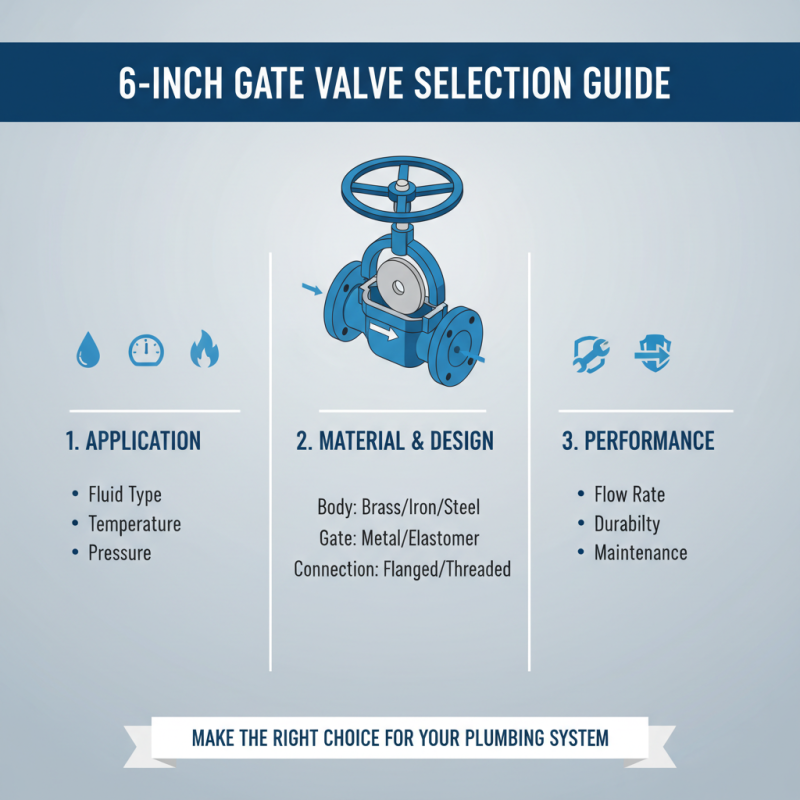

When selecting a 6 inch gate valve for your plumbing needs, several key considerations will help ensure you make the right choice. First, it is essential to determine the specific application for which the valve will be used. Consider factors such as the type of fluid that will flow through the valve, as well as the temperature and pressure conditions. These elements will dictate the material and design of the gate valve, ensuring it can withstand the operating environment without compromising performance.

Another crucial aspect to consider is the valve's sizing and compatibility with your existing plumbing system. Make sure to check the dimensions and the pressure rating of the valve to ensure a proper fit and function. Additionally, evaluating the ease of installation and maintenance is important. Some gate valves may offer features that allow for quicker repairs and replacements, which can save time and costs in the long run. By taking these considerations into account, you can select a 6 inch gate valve that effectively meets your plumbing requirements.

When selecting a 6-inch gate valve for your plumbing needs, the materials and construction of the valve are critical factors to ensure durability and optimal performance. Common materials used in gate valves include brass, stainless steel, and ductile iron. Each of these materials offers distinct advantages: brass is resistant to corrosion, stainless steel provides superior strength and longevity, while ductile iron combines resilience with cost-effectiveness. According to a report by the American Water Works Association, the longevity of a gate valve can significantly increase when utilizing high-quality materials, providing a lifespan of 25 years or more under normal operating conditions.

To enhance the durability of your gate valve, it’s essential to assess the valve’s construction, including the quality of the sealing surfaces and the design of the gate. Valves with forged bodies and precision-machined components tend to facilitate better sealing and can withstand higher pressures. The American Society of Mechanical Engineers highlights that valves designed with advanced engineering techniques can improve flow control and reduce maintenance needs.

**Tips:** Ensure that the gate valve has a protective coating to resist environmental damage, especially if it will be exposed to outdoor conditions. Additionally, consider the importance of proper installation; even the best materials can fail if not installed correctly. Regular maintenance checks can also help in identifying any wear or corrosion before they lead to significant issues.

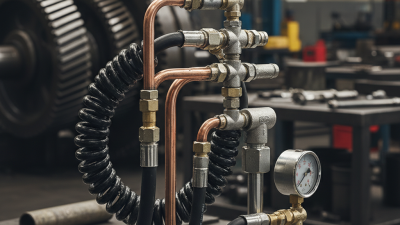

When selecting a 6-inch gate valve, one of the most critical factors to consider is the end connections of the valve. These connections determine how the valve interfaces with your plumbing system. Common types include threaded, flanged, and welded connections. It's essential to evaluate the existing plumbing infrastructure and ensure compatibility to avoid leaks and other issues. Take time to measure the current pipe diameter and the type of connection in use to ensure you choose a valve that fits seamlessly.

**Tips:** Always double-check the specifications of your pipe system before purchasing a valve. If your plumbing setup utilizes flanged connections, opt for a gate valve that features the same flange rating to ensure a proper fit. Additionally, consider the materials used for both the valve and the existing piping—compatibility can significantly impact the valve's performance and longevity.

Another crucial consideration is the pressure and temperature ratings of the valve. Ensure that the chosen valve can withstand the operating conditions of your plumbing system. This means checking that both the valve and the connection method are rated for the same levels of pressure and temperature your system will encounter during operation. Proper alignment of these factors can lead to optimal functionality and durability.

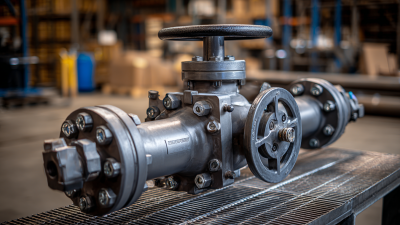

When it comes to maintaining 6-inch gate valves, proactive measures can significantly extend their lifespan and ensure reliable performance. Industry reports indicate that regular inspection and maintenance can increase the durability of these valves by up to 30%.

A key aspect of maintenance is periodic lubrication of the valve stem and operating mechanism. Ensuring that the threads are well-greased reduces friction and wear, thereby enhancing the overall functionality and extending the life cycle of the valve.

Additionally, flanged connections should be examined for leaks and tightness. Studies have shown that undetected leaks can lead to significant energy losses, with estimates suggesting that even minor leaks in a high-traffic system can result in annual losses exceeding thousands of dollars.

By routinely checking for leaks and retightening bolts as necessary, you can prevent unnecessary wear and preserve the integrity of the plumbing system. Moreover, it's crucial to flush the valve periodically to prevent debris accumulation, which can obstruct flow and damage components.

A consistent maintenance routine not only assures operational efficiency but also significantly lowers the risk of unexpected failures, contributing to smoother plumbing operations.