In the machinery maintenance industry, selecting the appropriate grease fitting sizes is a critical factor that can significantly influence the performance and longevity of equipment. According to a recent report by the Machinery Maintenance Association, nearly 40% of equipment failures can be attributed to inadequate lubrication, often stemming from the incorrect application of grease fitting sizes. Ensuring the right fit not only enhances grease delivery but also reduces the risk of over-lubrication, which can lead to increased wear and tear.

John Smith, a renowned lubrication expert and author of "The Science of Lubrication," emphasizes this point: "The success of a lubrication system hinges on selecting the correct grease fitting sizes. A well-chosen fitting can ensure optimal grease flow and protect machinery from potential failures." This insight serves as a valuable reminder for maintenance professionals to carefully consider the specifications of their equipment and choose grease fittings that match the unique requirements of each machine.

As the industry continues to evolve, understanding the nuances of grease fitting sizes will be essential for minimizing downtime and maximizing productivity. With proper knowledge and application, machinery operators can optimize their lubrication strategies, ultimately leading to improved operational efficiency and reduced costs over time.

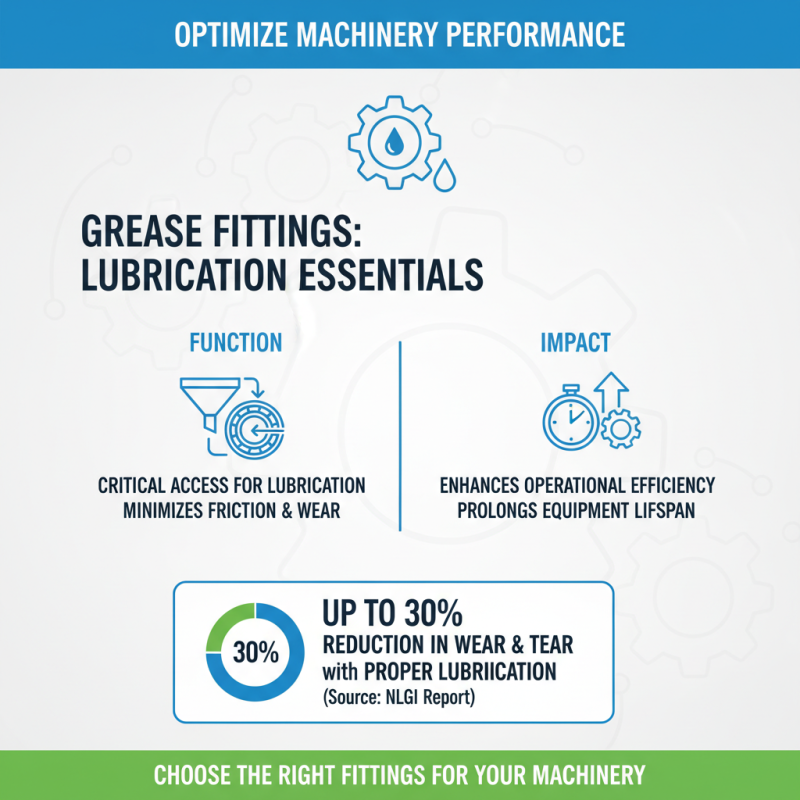

Grease fittings are essential components in many types of machinery, serving as critical access points for lubrication systems. By facilitating the application of grease, these fittings help minimize friction between moving parts, thereby enhancing operational efficiency and prolonging the lifespan of equipment. According to a report by the National Lubricating Grease Institute (NLGI), proper lubrication can improve machinery performance, leading to a potential 30% reduction in wear and tear. This emphasizes the importance of choosing the right grease fittings to match the specific lubrication needs of various machinery types.

Selecting the appropriate grease fitting size is crucial for ensuring that lubricant is delivered effectively to all required areas. Using an incorrect fitting size can result in improper grease flow, leading to insufficient lubrication that compromises machinery performance and increases the risk of breakdown. The NLGI also indicates that approximately 50% of machinery failures are attributed to inadequate lubrication. As such, understanding the sizing standards and compatibility with existing fittings not only plays a significant role in maintenance practices but also directly influences the operational reliability of machinery. Proper attention to these details is essential for any operation relying on mechanical systems.

Grease fittings are critical components in maintaining the efficiency and longevity of machinery. There are several types of grease fittings, each designed for specific applications. The most common include standard grease fittings, also known as Zerk fittings, which allow for easy lubrication of bearings and joints. They have a simple design that facilitates the injection of grease, ensuring smooth operation and reducing wear on moving parts.

Another popular type is the button head fitting, often used in tight spaces where a standard fitting might be too bulky. Its low profile makes it ideal for compact machinery or equipment where accessibility is limited.

Moreover, there are specialty grease fittings such as the 90-degree angled fittings and extended fittings, which cater to unique operational needs. The 90-degree fittings are perfect for applications where the greasing angle must be adjusted to reach certain components effectively. Extended fittings provide additional length for reaching hard-to-access areas.

Additionally, push-to-connect fittings are increasingly popular for their ease of use, allowing grease to be injected with minimal effort. Understanding these various types of grease fittings and their specific applications is essential for selecting the right ones to optimize machinery performance and reliability.

When it comes to machinery maintenance, selecting the correct grease fitting sizes is crucial for optimal performance and longevity. Accurately measuring and assessing grease fitting sizes starts with understanding the application requirements and the specifications outlined in the machinery's manual. Typically, grease fittings are categorized by their thread size and type, with common measurements ranging from 1/8 inch to 1/4 inch in diameter. Utilizing a caliper or a thread gauge can greatly enhance the precision of your measurements, ensuring compatibility with the grease guns and fittings used in your operations.

Additionally, it is important to assess the environment in which the machinery operates. Factors such as pressure, temperature, and exposure to contaminants can influence the choice of grease fitting sizes. For example, equipment operating under high pressure may benefit from fittings with enhanced sealing capabilities to prevent leakage. Furthermore, understanding the specific lubrication points on the machinery allows for a more tailored approach to selecting the appropriate fitting sizes, ultimately ensuring efficient grease application and extending the equipment's service life.

| Fitting Type | Size | Thread Pitch | Usage |

|---|---|---|---|

| Standard Grease Fitting | 1/4'' NPT | 18 TPI | General machinery |

| Metric Grease Fitting | M6 | 1.0 mm | European machinery |

| Straight Grease Fitting | 1/8'' NPT | 27 TPI | Compact spaces |

| Angled Grease Fitting | 1/8'' NPT | 27 TPI | Hard-to-reach areas |

| Button Head Grease Fitting | 1/4'' NPT | 18 TPI | Accessibility for manual greasing |

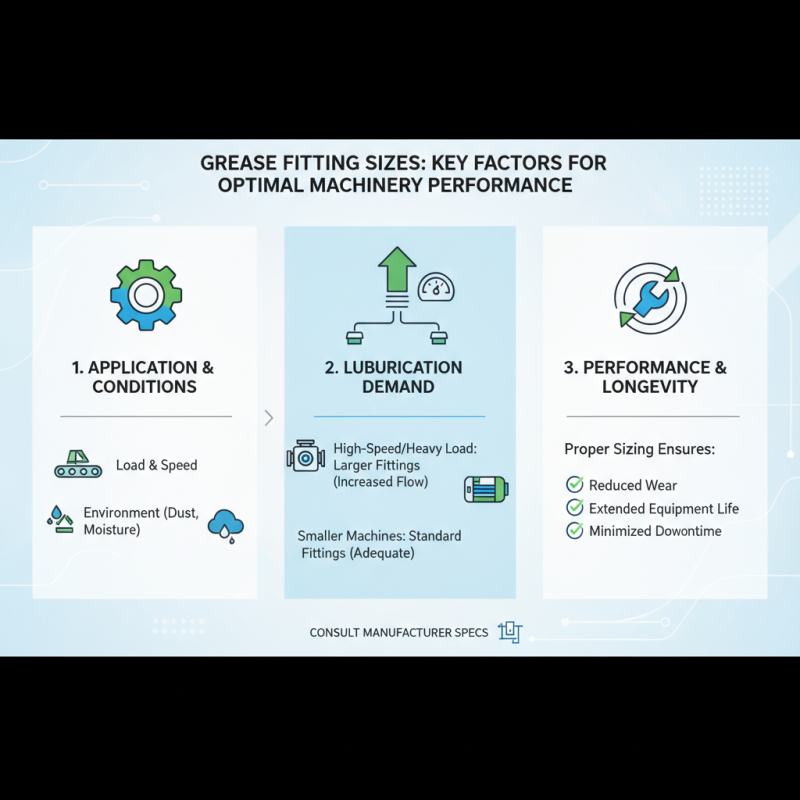

Choosing the appropriate grease fitting sizes for machinery is influenced by several critical factors that ensure optimal performance and longevity of equipment. One of the most significant considerations is the machinery's specific application and operating conditions. Different types of machinery may require varying amounts of lubrication based on their load, speed, and environment. For instance, high-speed or heavy-load machines typically necessitate larger fittings to accommodate increased grease flow and prevent wear. Conversely, smaller machines might perform adequately with standard fittings, highlighting the need for careful evaluation.

Another essential aspect to consider is the accessibility of grease fittings during maintenance. Adequate access can greatly influence the size and type of fitting selected; fittings should be positioned where they can be easily reached to facilitate regular lubrication. Additionally, the type of grease being used and its viscosity can determine the size of the fitting, as thicker greases may require larger openings to ensure they can be pumped efficiently. Understanding these factors is crucial for selecting the right grease fitting sizes, which ultimately impacts the maintenance efficiency and operational reliability of machinery.

When selecting grease fitting sizes for your machinery, avoiding common pitfalls can save you time and money. One frequent mistake is overlooking the specific requirements of your application. Each machinery type may require different fitting sizes based on operating conditions and lubricant viscosity. According to a study by the Society of Tribologists and Lubrication Engineers (STLE), improper grease fitting sizes can lead to lubrication failures, causing machinery to underperform and increasing wear rates by over 30%.

Another common error is failing to consider the environment in which your machinery operates. Harsh conditions such as extreme temperatures, dust, and moisture can impact the effectiveness of grease fittings. Choosing the wrong size or type may exacerbate these issues. A report from the International Organization for Standardization (ISO) suggests that proper selection of grease fittings can enhance operational lifespan by up to 25% in challenging environments.

Tip: Always refer to the machinery’s manual and specifications to find the recommended grease fitting sizes. Double-checking against standardized dimensions can help avoid mismatches.

Tip: When in doubt, consult with lubrication experts who can guide you on the best practices and fitting sizes suited for your specific machinery requirements. With their insights, you can make informed decisions that optimize your equipment's performance.