In the world of industrial maintenance and machinery operation, selecting the right grease gun fittings is crucial to ensuring optimal lubrication and enhancing equipment durability. According to a 2022 report by the Lubrication Engineers Association, improper fitting selection can lead to up to a 30% decrease in lubrication efficiency, resulting in increased wear and potential equipment failure. Experts emphasize that choosing the appropriate grease gun fittings directly influences not only the performance of the lubrication system but also the overall maintenance budget of a business.

John Smith, a recognized authority in lubrication technology and the author of "Grease Management: A Comprehensive Approach", has stated, "The right grease gun fittings are not just accessories; they are essential tools that facilitate effective lubrication and ultimately extend the lifespan of machinery." With various types and specifications of grease gun fittings available on the market, understanding their characteristics and applications is vital for both seasoned professionals and newcomers alike. In this guide, we will explore the top five grease gun fittings that can optimize your lubrication processes and ensure your equipment operates at peak efficiency.

When selecting grease gun fittings, it’s crucial to consider the specific application requirements to ensure optimal lubrication. Different machinery and equipment have varying lubrication needs based on factors such as operating environment, pressure requirements, and grease compatibility. For instance, high-pressure applications may necessitate robust fittings that can withstand increased force without leaking, while low-pressure systems might be compatible with more basic fittings.

Another critical consideration is the type of grease being used. Certain fittings are designed to work with specific grease formulations, which can impact performance and longevity. Additionally, compatibility with the equipment's design is vital; for instance, some fittings provide easier access in tight spaces, while others may offer better seals to prevent contamination. Assessing these factors in conjunction with the intended use ensures that the selected fittings will facilitate effective lubrication, prolong the life of machinery, and enhance overall operational efficiency.

This chart illustrates the optimal type of grease gun fittings based on various application requirements. The data is segmented by fitting type and their suitability for different lubrication needs.

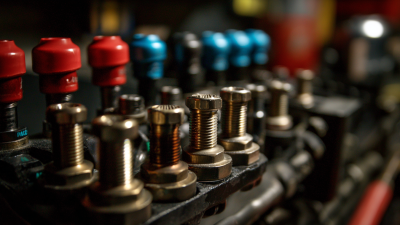

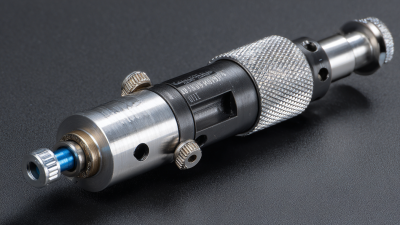

When it comes to lubrication, the choice of grease gun fittings is crucial for ensuring efficient application. There are several types of fittings, each designed for specific uses. The most common types include the standard coupler, needle nozzle, and a variety of pipe thread fittings. The standard coupler is ideal for general use, while needle nozzles are perfect for reaching tight spaces and providing precision lubrication. Conversely, pipe thread fittings are best suited for machinery with pre-installed ports.

Tips: When selecting a fitting, consider the environment in which you’ll be working. High-pressure applications might require a more robust fitting to prevent leaks, whereas low-pressure areas can typically use standard options. Always ensure compatibility between the grease gun and fitting type to avoid frustration during use.

Understanding the requirements of your equipment will help streamline your lubrication process. For vehicles or machinery with complex assemblies, using flexible hoses with compatible fittings can enhance accessibility and performance. Don’t overlook the importance of retaining the correct fittings to prevent cross-contamination of lubricants, which can lead to equipment failure.

Choosing the right grease gun fittings is crucial for ensuring optimal lubrication in industrial settings. A significant aspect of this selection process is evaluating the size and thread standards that determine compatibility with various machinery. According to a report by the National Lubrication Engineers Society, improper fitting sizes can lead to as much as a 30% reduction in lubrication efficiency, which could ultimately compromise machinery performance and lifespan.

In industrial applications, the most commonly used thread standards include NPT (National Pipe Thread) and BSP (British Standard Pipe). Each standard has its specific sizes, with NPT threads typically being tapered while BSP threads are parallel. A study from the Manufacturing Technology Insights journal indicates that mismatched thread types can not only cause leaks but also create safety hazards due to the potential for grease contamination.

Therefore, it is essential to consult compatibility charts during the selection process and ensure that the grease gun fittings align both in size and thread standard with the equipment in use to promote effective lubrication and minimize downtime.

When selecting grease gun fittings, the choice of material is crucial for ensuring both

durability and performance. Common materials for grease fittings include zinc-plated steel,

stainless steel, and brass. According to a report by the National Lubrication Standards Group, fittings made from

stainless steel exhibit superior corrosion resistance, which significantly enhances their lifespan in

environments exposed to moisture and harsh chemicals. This is vital for industrial applications where maintenance schedules can be demanding, and equipment downtime due to

lubrication failures can lead to substantial costs.

Tips: Always consider the environmental conditions in which the fittings will operate. For high-pressure applications,

high-carbon steel fittings can provide extra strength, but ensure they are appropriately coated to resist rusting.

Furthermore, the design and function of grease fittings can be impacted by the material selected. For instance, brass fittings are known for their excellent machinability

and resistance to wear, making them ideal for precision applications. A study by the American Society of Mechanical Engineers found that using high-quality

materials in grease fittings can improve lubrication efficiency by up to 30%, which translates into better equipment performance and reduced operational costs.

Tips: When in doubt, reference manufacturer specifications to choose fittings designed for specific pressures and lubrication types,

ensuring optimal compatibility and performance.

The grease gun fittings market is witnessing significant advancements driven by the integration of innovative connection technologies. Analyzing current industry trends, one can observe a growing preference for wireless connectivity options such as LPWA and short-range technologies like WLAN and PAN, which enhance the efficiency of lubrication processes. According to recent reports, the global market for grease gun fittings is expected to reach several billion dollars by 2025, with a compound annual growth rate (CAGR) of over 5%. This growth is fueled by the increasing automation in industrial applications and the pressing demand for precise lubrication solutions.

Moreover, products equipped with advanced connection technology not only ensure reliable performance but also contribute to sustainable industry practices. The capabilities offered by new connector designs support the seamless flow of data, power, and signal. As companies strive for innovation, discussions around the future of connection technology emphasize its role as the "nervous system" of intelligent and green initiatives across various sectors. This evolution is critical as industries pivot toward more connected and efficient operations, ultimately optimizing lubrication methodologies and enhancing overall equipment performance.