Choosing the right grease gun fittings can significantly impact your maintenance tasks. According to John Smith, a leading expert in lubrication systems, “The right fittings ensure efficiency and longevity.” His insight emphasizes the importance of selecting compatible components.

Grease gun fittings come in various styles and sizes. Understanding these differences is crucial for seamless operation. Conversely, many users often overlook the specifications. This oversight can lead to inefficiency and frustration. Selecting the wrong fitting can result in leaks or improper lubrication, affecting equipment performance.

It's essential to assess your specific needs. Factors like equipment type and operating conditions matter. For instance, a high-pressure environment requires robust fittings. Reflecting on the choices available can help you avoid costly mistakes. Taking the time to research can lead to better outcomes. In the grease gun fittings industry, a thoughtful approach makes all the difference.

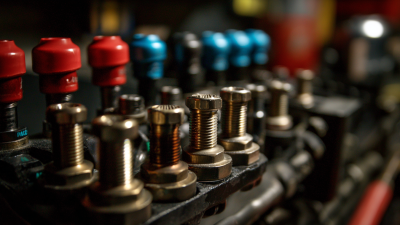

When choosing grease gun fittings, understanding the different types is crucial. There are three main types: standard, locking, and quick disconnect fittings. Each serves a specific purpose and can significantly affect how efficiently you can apply grease.

Choosing the right grease gun fittings starts with understanding your equipment. Each setup is different. Not all fittings match every tool. Compatibility is crucial in achieving effective lubrication. Misalignment can lead to wasted resources and inefficient workflows.

Consider the type of grease. Different machines require various levels of viscosity. A study by the Society of Tribologists and Lubrication Engineers highlights that incorrect grease can result in up to 40% increase in wear. Assess the specifications of your tools before making a choice. Check the manufacturer’s guidelines to ensure you select the best fit.

Tips: Always have a few common fittings on hand. This can save you downtime. Regularly inspect your fittings for wear. This keeps your tools working effectively. Small issues often lead to larger problems. Stay proactive in your maintenance schedule to avoid costly repairs.

This chart illustrates the compatibility of different types of grease gun fittings with standard equipment types based on user evaluations. The data is represented in a bar graph, providing a clear comparison for users to identify which fitting types best match their needs.

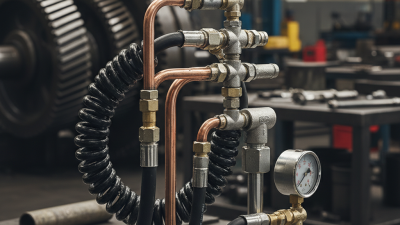

Choosing the right grease gun fittings begins with understanding pressure requirements. Each application demands different pressure levels. A fitting that works for one task may not suit another. Low-pressure fittings can struggle under high demand. This mismatch can lead to failures, wasting time and resources.

Assessing pressure requirements is crucial for optimal performance. Consider the machinery or equipment you are using. For high-performance tools, select fittings rated for higher pressures. This prevents leaks and ensures efficient grease delivery. If you're uncertain, conducting tests can help identify the most effective fitting. Sometimes, trial and error is part of the process.

Remember, flexibility is key. Some fittings may not meet your needs perfectly. Be prepared to adjust your choices based on performance. Gathering feedback from colleagues or users can offer valuable insights. Each fitting has its strengths and weaknesses. Finding the right balance is essential for success.

| Fitting Type | Pressure Rating (psi) | Compatible Grease Guns | Application |

|---|---|---|---|

| Standard Grease Gun Fitting | 2500 | Manual Grease Guns | General Lubrication |

| Angled Fitting | 3000 | Pneumatic Grease Guns | Hard-to-Reach Areas |

| Locking Fitting | 3500 | Electric Grease Guns | High-Pressure Applications |

| Quick-Connect Fitting | 4000 | Industrial Grease Guns | Fast Lubrication |

When selecting grease gun fittings, material and durability are critical. These factors greatly influence the longevity of your tools. Common materials include steel, aluminum, and plastics. Steel fittings typically offer high durability but may corrode over time. Aluminum is lighter and resistant to rust but may not withstand heavy use. Plastics are cost-effective but often lack sturdiness.

Consider your work environment. If exposed to extreme temperatures or humidity, choose materials that can endure these conditions. Inspect the fittings regularly for wear and tear. A small crack can lead to leaks and inefficiencies.

Tips: Always choose high-quality fittings for heavy-duty applications. Metallic options generally last longer. If you’re unsure, consult manufacturers' guides for material specifications. Remember, a little research ensures you make a better choice. Be cautious of lower-priced fittings; they may lead to costly repairs in the long run.

Maintaining grease gun fittings is essential for optimal performance. Regular inspection helps you identify wear and tear. Check the coupler for proper sealing. A worn coupler may lead to leaks and inefficiency. Tighten loose fittings to prevent excess grease loss. This simple step makes a big difference.

Cleaning fittings is equally important. Dust and dirt can clog the grease passage. Use a clean rag to wipe away grime. Keep a brush handy for harder-to-reach areas. A bit of maintenance goes a long way. However, it’s easy to overlook these tasks in a busy workshop.

Consider your environment. Moisture and dirt can accelerate corrosion. Store your grease gun in a dry place. Also, adapt your maintenance routine to the frequency of use. If you grease frequently, check fittings more often. Be proactive rather than reactive to save time and money.