In the ever-evolving landscape of lubrication technology, selecting the right pneumatic grease pump has become increasingly crucial for efficiency and performance. As industry expert John Smith points out, “The right pneumatic grease pump is not just a tool; it’s an investment in long-term maintenance and productivity.” Choosing the ideal pump plays a significant role in achieving optimal grease delivery while also reducing downtime and enhancing equipment lifespan.

As we approach 2025, understanding the key factors that influence the effectiveness of a pneumatic grease pump is imperative for both professionals and businesses alike. With numerous options available on the market, it can be overwhelming to discern which features best align with specific operational needs. From pressure ratings to pump construction and compatibility with various grease types, each element significantly impacts the pump's performance. This article will unravel the essentials of selecting the best pneumatic grease pump tailored to your requirements, ensuring you make an informed decision that will benefit your operations in the years to come.

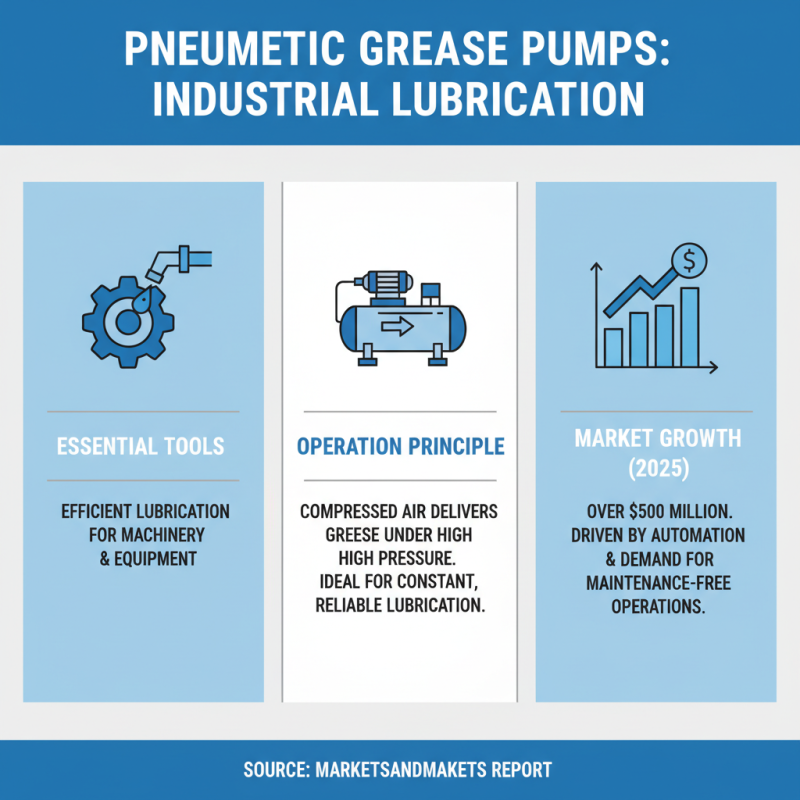

Pneumatic grease pumps are essential tools in a variety of industrial applications, providing efficient lubrication for machinery and equipment. Their operation relies on compressed air to deliver grease under high pressure, making them ideal for environments requiring constant and reliable lubrication. According to a report by MarketsandMarkets, the pneumatic grease pump market is expected to grow significantly, reaching a valuation of over $500 million by 2025 due to increasing automation in manufacturing sectors and the growing demand for maintenance-free operations.

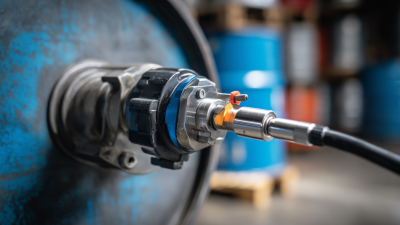

Applications of pneumatic grease pumps span across multiple industries, including automotive, construction, and manufacturing. In automotive maintenance, for instance, pneumatic pumps facilitate quick and clean application of grease, enhancing vehicle lifespan and performance. Moreover, these pumps are suitable for high-volume grease dispensing, ensuring that large machinery in factories operates smoothly and without downtime. Industrial reports indicate that effective lubrication can reduce friction-related wear by up to 50%, highlighting the critical role pneumatic grease pumps play in prolonging machinery life and minimizing maintenance costs.

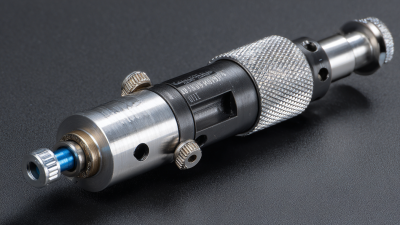

Understanding the specific requirements of your operation is crucial when choosing a pneumatic grease pump. Factors such as the viscosity of the grease, the pump's output pressure, and the specific application environment significantly influence pump performance. With advancements in technology, modern pneumatic grease pumps are designed for versatility, allowing users to switch between different types of lubricants while maintaining an efficient workflow.

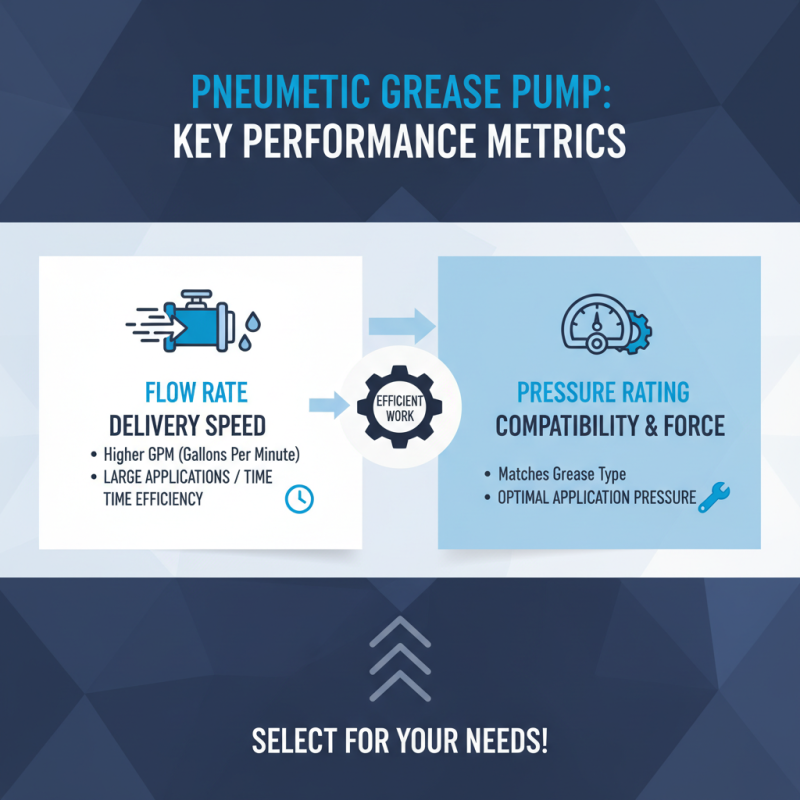

When selecting a pneumatic grease pump, several key features should be prioritized to ensure optimal performance and efficiency. First and foremost, consider the pump's flow rate, which is a critical factor influencing its ability to dispense grease quickly and effectively. Industry reports indicate that pumps with a higher flow rate, generally above 5 kg/min, are preferred for high-demand applications, allowing users to complete lubrication tasks more swiftly and reduce downtime in operations.

Another important feature to assess is the maximum pressure capability of the pump. A pneumatic grease pump that can generate pressures between 50 and 100 psi is typically sufficient for most applications, including automotive and heavy machinery sectors. This is crucial for ensuring that the grease can reach all necessary components, particularly in tighter spaces. Additionally, look for features such as adjustable dispensing and compatibility with various grease types, which enhance versatility and ease of use. Reports suggest that customizable options enhance user satisfaction, indicating that flexibility in application is a sought-after quality in today’s market.

Lastly, portability and ease of operation should not be overlooked. A pump that combines lightweight design with ergonomic features can significantly improve user experience and efficiency. Data from industry surveys reveal that ergonomic designs lead to a 30% reduction in operator fatigue, highlighting the importance of selecting a pump that is not only functional but also user-friendly. By focusing on these features, users can effectively choose a pneumatic grease pump that meets their specific needs in 2025.

| Feature | Importance | Recommendations |

|---|---|---|

| Max Pressure | High pressure allows for efficient grease application. | Look for pumps with a max pressure of at least 40 PSI. |

| Flow Rate | Higher flow rates mean less time spent pumping. | Select a pump with a flow rate over 6 oz/min. |

| Tank Capacity | Larger tanks reduce the need for frequent refills. | Consider models with at least a 5-gallon tank. |

| Weight | Portable pumps enhance usability in various settings. | Choose a lightweight model (under 40 lbs) for easier transport. |

| Ease of Use | User-friendly features improve efficiency and safety. | Look for ergonomic handles and easy-to-read gauges. |

When selecting a pneumatic grease pump in 2025, understanding the distinctions between top brands is crucial for meeting specific application needs. Leading manufacturers tend to focus on ergonomic design, optimizing performance and usability for various environments, from automotive workshops to industrial facilities. Key features to consider include flow rate, dispensing pressure, and the pump's compatibility with different grease types. Comprehensive comparisons often highlight how certain brands excel in durability and maintenance, ensuring longevity and reliability under heavy usage.

Moreover, technology trends play a significant role in shaping the offerings of pneumatic grease pumps. Innovations such as integrated pressure regulators and digital display systems are becoming increasingly common, enhancing user experience and precision in grease delivery. Assessing the customer support and warranty policies of various brands can also provide insights into long-term value and dependability. By analyzing these elements, users can make informed decisions that align with their operational requirements while maximizing efficiency and performance.

When selecting a pneumatic grease pump, evaluating performance metrics is essential to ensure that you meet your specific needs. One of the primary aspects to consider is the flow rate, which indicates how quickly the pump can deliver grease. A higher flow rate is beneficial for larger applications or where time efficiency is critical. Additionally, the pressure rating of the pump is crucial; it should be compatible with the grease type and application pressure required for optimal performance. Researching the maximum pressure the pump can achieve will help you determine its suitability for different tasks.

Another important specification to assess is the pump's material compatibility and durability. Materials used in the construction of the pump can affect its lifespan and reliability. Look for pumps that can withstand harsh working conditions and corrosive substances associated with certain greases. Moreover, consider the ease of maintenance and availability of replacement parts, as these factors can significantly impact the long-term performance and usability of the pump. By focusing on these key performance metrics and specifications, you can ensure that the pneumatic grease pump you choose in 2025 will meet your demands effectively.

When selecting a pneumatic grease pump, the balance between cost and quality is a crucial consideration. Many consumers may initially lean towards budget-friendly options, eager to save money. However, it's important to remember that a cheaper price tag can sometimes mean compromised quality, which might lead to higher costs in the long run.

Investing in a reliable grease pump can enhance operational efficiency and reduce the frequency of maintenance and repairs.

To make a budget-friendly choice without sacrificing quality, consider the pump's construction materials and design efficiency. Look for durable components that can withstand demanding work environments, as well as user-friendly features that streamline the application process.

Reading reviews and gathering feedback from other users can also provide insights into a product's performance and longevity, helping you identify options that offer the best value for your money. By prioritizing these factors, you can make an informed decision that meets both your financial and operational needs.