Choosing the right grease coupler can seem overwhelming. With many options available, it’s essential to understand your specific needs. A grease coupler connects your grease gun to fittings on machinery. This connection affects how effectively you can lubricate equipment.

When selecting a grease coupler, consider compatibility. Not all couplers fit every grease fitting. Some might require adaptors, which can complicate your work. The design of the coupler also plays a role in ease of use. Look for features that enhance comfort, such as grips that reduce slipping.

Think about the environment where you will use the grease coupler. Will it be a clean workspace or a dirty automotive shop? Conditions matter. Assess how difficult it could be to use your coupler in various situations. Reflecting on these details helps ensure you make the best choice for your lubrication tasks.

Grease couplers are essential tools for efficient lubrication. They connect grease guns to various machinery. Understanding their functionality is crucial for maintenance tasks. A good coupler ensures no grease leaks. It creates a tight seal, allowing for precise application.

Different types of grease couplers exist. Some are designed for high-pressure systems. Others work better with low-pressure equipment. It’s important to consider your machinery when selecting a coupler. A mismatch can lead to frustrating experiences. Notably, the ease of connection can vary. Sometimes, couplers can be tricky to attach or detach.

Choosing the right coupler is not always straightforward. Users often overlook compatibility issues. Some couplers may not fit all grease ports. This could lead to improper lubrication. Regularly checking the coupler for wear is a good practice. A damaged coupler can compromise performance. Reflecting on these choices can improve maintenance routines.

| Grease Coupler Type | Compatibility | Max Pressure (psi) | Benefits | Ideal Usage |

|---|---|---|---|---|

| Standard Grease Coupler | Grease guns, standard fittings | 3000 | Versatile, easy to use | General lubrication tasks |

| Locking Grease Coupler | 1/8" NPT (national pipe thread) | 5000 | Secure connection, minimizes leaks | Heavy-duty applications |

| Manual Grease Coupler | Grease cartridges | 2000 | Economical, simple design | Light-duty use |

| Pneumatic Grease Coupler | Air-powered grease guns | 6000 | Efficient for high-volume applications | Automotive and industrial use |

| Hydraulic Grease Coupler | Hydraulic systems | 7000 | High-pressure resistance | Heavy machinery |

When selecting a grease coupler, understanding the types available is essential. The market offers several options. Each type has specific features that cater to different needs. For instance, standard couplers are widely used. They are compatible with most grease fittings. However, in some cases, their performance might not meet high-pressure demands.

Some couplers focus on high-pressure applications. These are ideal for heavy machinery and industrial use. They often feature enhanced sealing mechanisms. This ensures grease delivery under demanding conditions. According to industry reports, 35% of professionals prefer high-pressure models for equipment care. Yet, they can be more expensive.

Tip: Always consider the compatibility of the grease coupler with your equipment. A mismatched coupler could lead to failures.

Another option is the quick-connect coupler. This type allows for faster operation. It saves time during maintenance tasks. However, users might find them less durable compared to standard options. Regular inspections are necessary to avoid equipment issues.

Tip: Keep an eye on wear and tear. Replace any worn-out connector immediately to prevent leaks.

In choosing the right coupler, reflect on your specific needs. Think about the environment it will be used in. Assess the frequency of use. Such considerations can lead to better functionality and lower long-term costs.

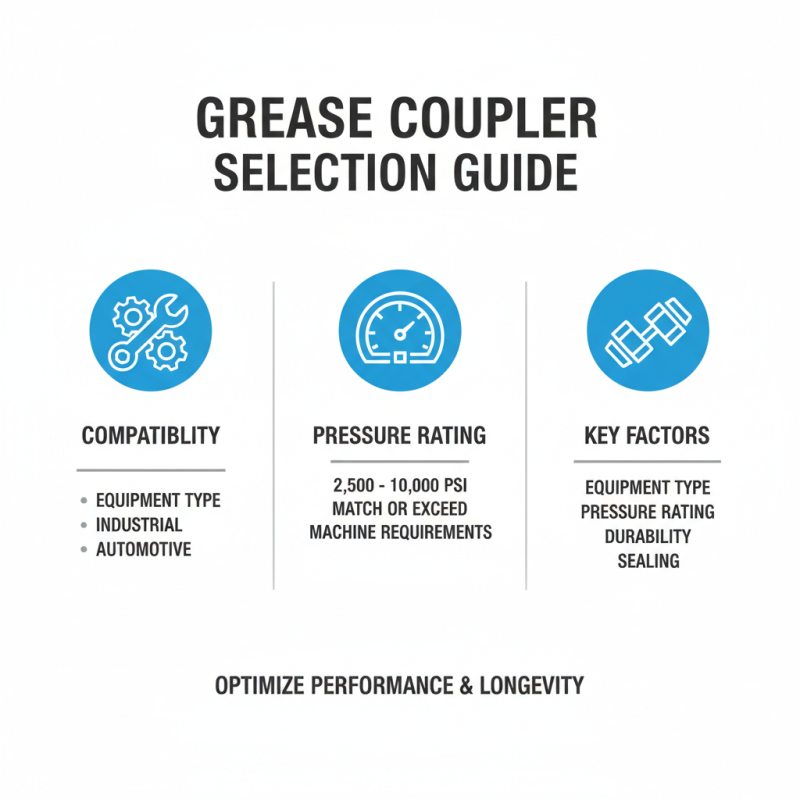

Choosing the right grease coupler involves several key factors. Compatibility with your equipment is crucial. Different types of couplers suit various machines, including industrial and automotive applications. You need to consider the pressure ratings as well. Reports indicate that most grease couplers can handle pressures from 2,500 to 10,000 PSI. Ensure that the coupler you select meets or exceeds your machine's requirements.

Another important factor is the material of the coupler. Common materials include steel, stainless steel, and plastic. Steel is robust but may corrode over time. In contrast, stainless steel offers more durability in harsh environments. According to industry research, choosing the right material can enhance productivity by up to 30%. Design features also matter. Some couplers have a swivel tip, making them easier to maneuver into tight spaces.

Lastly, don't overlook the maintenance aspect. A greaser that’s difficult to clean may lead to grease buildup, impacting performance. Research indicates that poor maintenance can reduce equipment lifespan by 20%. Selecting a grease coupler is not just about preference; it's about ensuring efficiency and longevity in your operations. Consider these factors carefully to make an informed decision.

Choosing the right grease coupler involves understanding its compatibility with both your equipment and the types of grease used. Several types of couplers exist, and they must fit your equipment’s specifications. Mismatched couplers can lead to ineffective lubrication or even equipment damage. For instance, a report by the National Lubricating Grease Institute indicates that improper lubrication costs companies millions annually due to equipment failures.

When selecting a coupler, examine the grease type you use. Different greases have unique formulations, which can affect performance. For example, lithium-based greases are common, but some equipment may require synthetic options. The variations in temperature and pressure can influence which coupler works best. Thus, knowing the compatibility chart for your grease type is essential for optimal performance.

Tip: Always consult your equipment manual. Make sure to match the coupler to the specific application. Consider investing in a multi-purpose coupler if your needs vary. This can simplify your inventory and increase efficiency.

Remember, an ill-fitted coupler may not just affect lubrication but can also contribute to increased wear and tear. Pay attention to the details in your selection to avoid costly mistakes down the line. Compatibility is crucial for equipment longevity and performance.

This chart illustrates the compatibility scores of different grease couplers with various equipment and grease types. A higher score indicates better compatibility for specific applications.

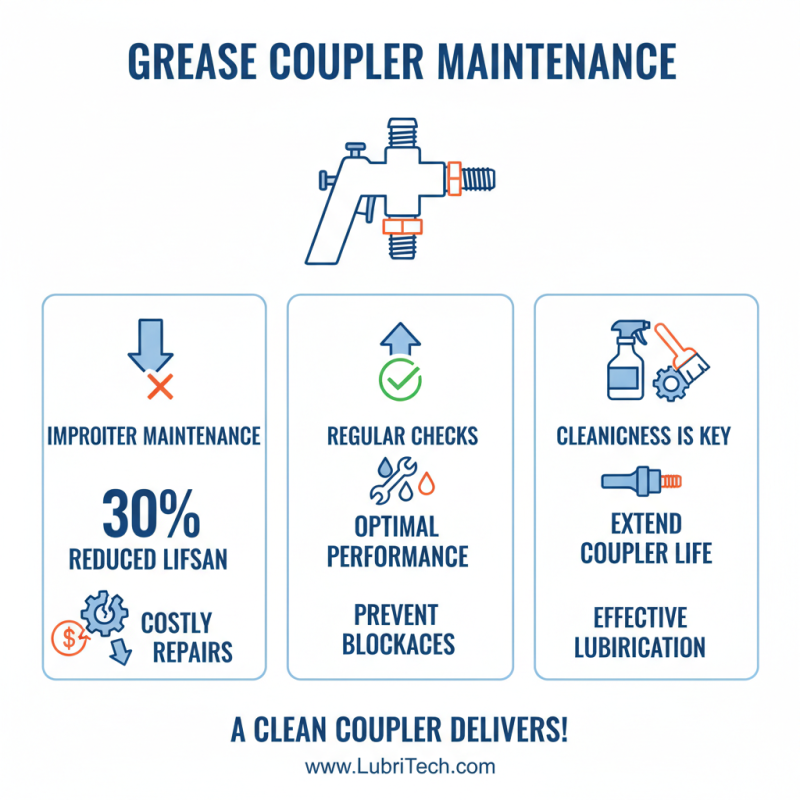

Maintaining grease couplers is crucial for optimal performance. A recent industry report indicates that improper maintenance can reduce their lifespan by up to 30%. Regular checks can help prevent costly repairs. Ensure the coupler is clean before use. Dirt and debris can cause blockages and affect lubrication. Remember, a dirty coupler won’t deliver grease effectively.

Inspect the coupler’s sealing. A worn or damaged seal can lead to grease leakage. According to studies, around 20% of maintenance issues stem from seal failures. Replacing seals regularly is a simple yet effective step. It can save you from bigger problems down the line.

Use the right grease for your coupler type. Not all greases are compatible, and using the wrong type can lead to greaser malfunction. Keep track of the grease used for each application. This practice helps in making informed choices during maintenance. Mistakes happen. Documenting your procedures is key for improvement. Adjusting your care routine as needed can enhance performance significantly.