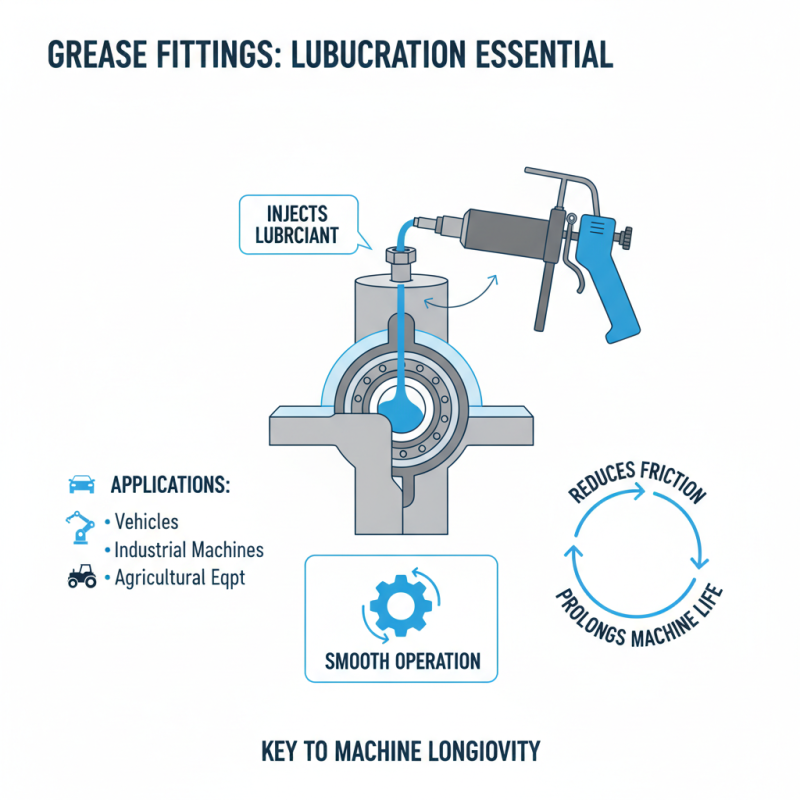

Grease fittings are small yet essential components in various machines. They allow for efficient lubrication, reducing friction and wear. Mark Thompson, a lubrication expert at TechLube Solutions, once stated, “Grease fittings keep machinery running smoothly and extend equipment life.”

These fittings serve a critical role in industries like automotive, manufacturing, and construction. They connect grease guns to machinery, ensuring proper lubrication at critical points. Regular maintenance using grease fittings can prevent breakdowns. However, neglect can lead to serious issues.

Many overlook the importance of grease fittings. They might ignore the need for grease until problems arise. This could prove costly in repairs and replacements. Awareness of proper lubrication practices is often lacking in the industry. Addressing these practices could enhance productivity. Implementing regular checks and maintenance could save time and money in the long run.

Grease fittings, often known as zerk fittings, play a crucial role in machinery maintenance. These small devices allow for the easy application of lubricant to moving parts. By connecting a grease gun to the fitting, users can inject grease directly into the part. This design helps prevent wear and tear, extending the equipment's lifespan by an estimated 30%.

Regular lubrication is vital. A recent industry report showed that equipment failures attributed to insufficient lubrication can account for 40% of mechanical issues. Grease fittings are particularly effective in areas prone to friction. They create a sealed environment, which helps keep dirt and moisture out. However, if not properly maintained, these fittings can become clogged. A blocked fitting can lead to serious damage—a concern often overlooked by operators.

In practice, not all grease fittings work perfectly every time. Over-greasing can create pressure build-up, potentially damaging seals. It’s important to follow guidelines. The lack of a consistent maintenance routine can lead to decreased efficiency. Focus on understanding the necessary maintenance for specific machinery. Proper handling of grease fittings significantly affects overall machine performance.

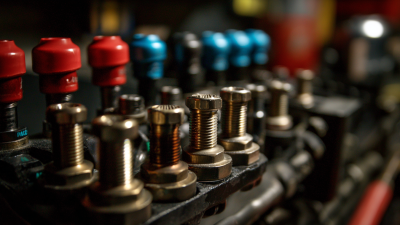

Grease fittings are an essential part of machinery maintenance. They help ensure smooth operation by providing a means to lubricate moving parts. Among the various types, standard, angled, and specialty grease fittings serve unique purposes. Each type has specific applications that cater to different machinery needs.

Standard grease fittings are the most common. They usually feature a straight design, allowing for easy access in many applications. According to industry reports, about 70% of all grease fitting installations use this type. However, they may be difficult to reach in tight spaces. Angled grease fittings, which offer a 45 or 90-degree angle, improve accessibility. They are valuable in machinery where standard fittings cannot be easily reached. Approximately 25% of functions reported require angled fittings for proper lubrication.

Specialty variants are available for unique applications. These may include one-way or shielded fittings. They provide solutions for unusual machinery configurations. Industry data indicates that these fittings reduce maintenance downtime by up to 30%. Though more effective, they can be costly and may not always be necessary. Understanding the right type of grease fitting for a specific application is crucial. It can prevent over-lubrication or, worse, mechanical failure.

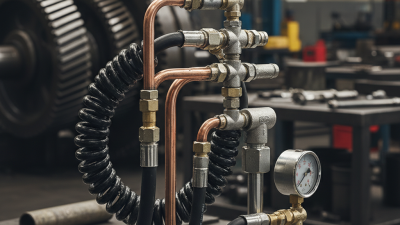

Grease fittings are small mechanical components found in various machines and vehicles. They provide a critical function in lubrication, ensuring moving parts operate smoothly. These fittings allow for grease to be injected directly into the components that require it. The process sounds simple, yet it plays a vital role.

When you apply grease through the fitting, it travels through a narrow channel. This channel directs the lubricant to crucial areas, like bearings or joints. Grease fills spaces, displacing harmful debris. Over time, contamination can build up, leading to potential failure. Regular maintenance is essential. Not keeping up with this process can result in premature wear.

The effectiveness of grease fittings depends on proper usage. If used incorrectly, you risk introducing unnecessary air or contaminants into the system. Observing grease quantities is also fundamental. Over-greasing can cause seals to leak, while under-greasing can lead to friction and damage. Understanding the mechanism of grease fittings is not just about knowing what they do but also realizing their limitations. Each machine has its own needs and usage pattern, which influences lubrication. It's always a good idea to educate oneself about these specifics.

Grease fittings are essential components found in various machines, ensuring smooth operation and reducing wear. They play a crucial role in machinery maintenance. Proper lubrication can significantly extend the lifespan of moving parts. Without regular grease application, machines may experience increased friction, leading to breakdowns.

Tips: Regularly check grease levels. It's easy to overlook this step. Grease fittings can be hard to access sometimes. Make it a habit to inspect these areas during routine maintenance.

Maintaining grease fittings is about more than just lubrication. Proper maintenance helps prevent costly repairs in the long run. Neglecting grease points can lead to drastic outcomes. The benefits include improved efficiency and reduced downtime. However, remember that over-greasing can cause issues too.

Tips: Use the right amount of grease. Too much can damage seals. Understand your machinery's needs, as each type may vary.

In mechanical systems, preventive care is vital. Without it, small problems can snowball into major failures. Regular attention to grease fittings is a simple yet effective maintenance practice. It's an area worth focusing on, even if it seems minor.

Grease fittings are essential components in machinery, ensuring smooth operation and reducing wear. The quality of grease fittings is often dictated by industry standards. These standards define both the materials used and the dimensions required for efficacy. For instance, the American National Standards Institute (ANSI) has specific guidelines that address the performance and safety requirements of lubrication fittings.

Research shows that improperly manufactured grease fittings can lead to equipment failure. A report by the Society of Automotive Engineers (SAE) indicates that up to 25% of lubrication fitting issues stem from subpar materials or design flaws. Such issues can cause significant downtime and repair costs. Choosing fittings that comply with these standards is crucial for mechanical reliability.

Tips: Always inspect grease fittings for wear and tear. Regular maintenance can prevent costly repairs. Utilize fittings made from high-quality materials to ensure long-term operation. Remember, not all fittings are created equal; adherence to industry specifications is key.