When it comes to maintaining machinery and ensuring optimal performance, understanding the tools available to you is crucial. One such tool that plays a pivotal role in lubrication is the grease gun. However, the effectiveness of a grease gun largely depends on the type of grease gun ends used. These ends come in various designs and functionalities, each tailored for specific applications. Whether it's for automotive maintenance, industrial machinery, or home equipment, knowing the different types of grease gun ends can significantly enhance the efficiency of your lubrication tasks.

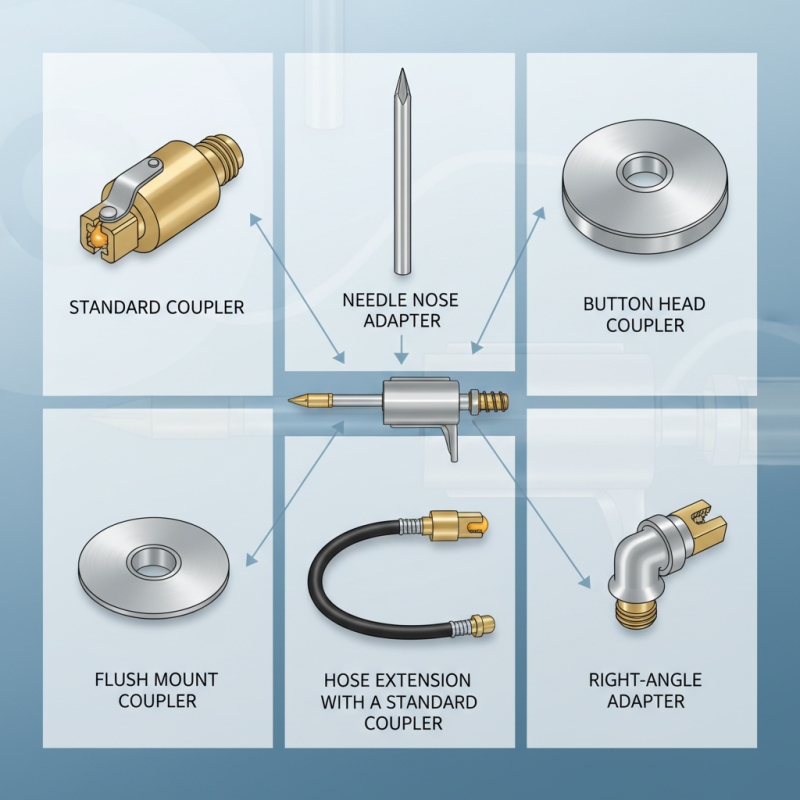

The diversity in grease gun ends allows users to choose the most suitable attachment for their needs, ensuring that the lubricant reaches all the necessary components with ease. From standard couplers to specialized nozzles, each type serves a unique purpose and can make a substantial difference in the application process. By familiarizing yourself with these tools, you not only save time but also extend the life of your equipment through proper maintenance.

In this article, we will delve into the various types of grease gun ends, their specific applications, and the benefits of using the right attachment for the job. Understanding these elements is essential for anyone looking to optimize their grease application processes and maintain their machinery effectively.

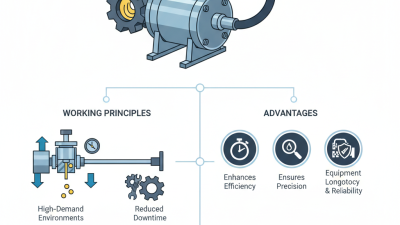

Understanding the importance of grease gun ends is essential for anyone involved in maintenance and lubrication tasks. The end fittings of a grease gun play a critical role in ensuring that the lubricant is applied effectively and efficiently. Different types of grease gun ends are designed for various applications, enabling users to achieve optimal results based on their specific lubrication needs. By selecting the appropriate end, users can improve the precision of grease application, reducing waste and enhancing overall lubrication performance.

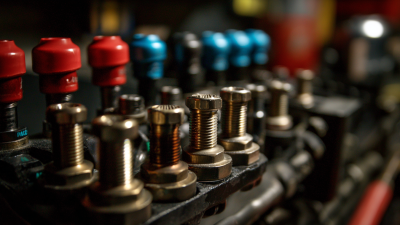

Moreover, the compatibility of grease gun ends with various grease fittings is vital for maintaining machinery and equipment. Each type of end fitting, whether it's a standard coupler or a specialized adapter, provides distinct advantages that cater to different environments and machinery designs. Understanding these differences helps technicians choose the right tool for their tasks, ultimately prolonging the lifespan of equipment and decreasing the likelihood of damage due to improper lubrication. In an era where equipment efficiency is paramount, knowing how to utilize the right grease gun ends can make a significant impact on the smooth operation of machinery.

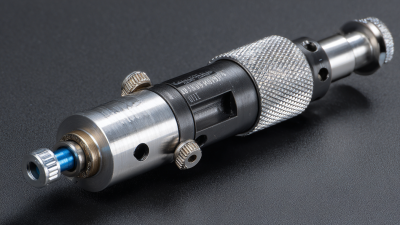

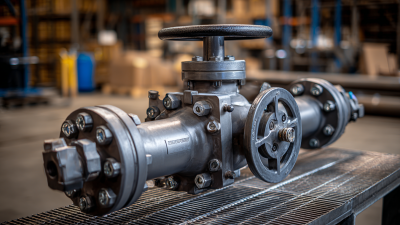

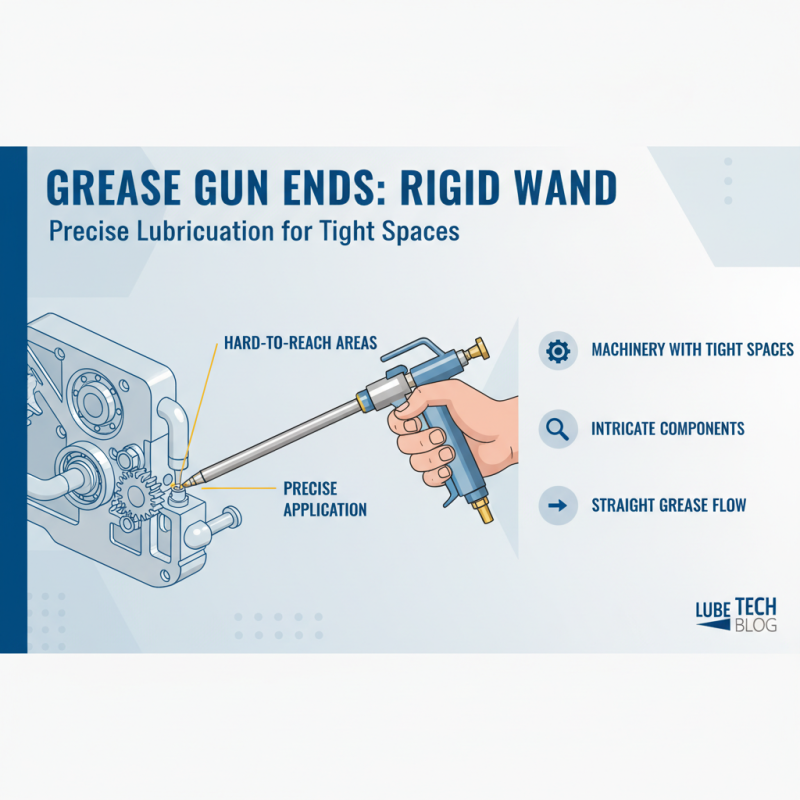

Grease guns are essential tools for maintaining machinery and equipment, and understanding the various types of grease gun ends is crucial for effective lubrication. Common types include the rigid wand, flexible hose, and coupler. The rigid wand is a straightforward option that allows precise application, ideal for hard-to-reach areas and offering a straight path for grease flow. This type is particularly beneficial for machinery with tight spaces or intricate components.

On the other hand, the flexible hose attachment is designed for versatility, allowing ease of access to those awkward angles and spaces. It can bend and maneuver around obstacles, making it perfect for automotive applications and other heavy machinery. Additionally, the coupler is another option that enhances the versatility of a grease gun, as it connects firmly to grease fittings, ensuring a secure application without leakage. Understanding these different types not only helps in selecting the right tool for the job but also in achieving optimal performance from your equipment.

When it comes to grease gun couplers, the choice between fixed and swivel types significantly impacts efficiency and usability in lubrication tasks. Fixed couplers provide a more straightforward connection, making them reliable for tasks that require a steady and secure attachment to grease fittings. According to a report from the National Lubricating Grease Institute, fixed couplers are preferred in environments where users prioritize durability and minimal movement, as they tend to have fewer mechanical parts that can fail.

However, swivel grease gun couplers are lauded for their flexibility, allowing users to maneuver in tight spaces with ease. This feature reduces the strain on the user and the risk of damage to the equipment. Research by the Equipment Lubrication Magazine reveals that swivel couplers can enhance productivity by up to 30% in complex applications, as they reduce the need to reposition the grease gun frequently. This advantageous design caters to situations where multiple angles of access are necessary, supporting maintenance activities in automotive and industrial settings alike.

Understanding the differences between these couplers is vital for operators to select the right tool for their needs. The right choice not only boosts efficiency but also ensures that lubrication is distributed evenly and effectively, contributing to the longevity of machinery and equipment. By keeping these industry insights in mind, professionals can significantly improve their lubrication routines and overall equipment maintenance strategies.

| Feature | Fixed Grease Gun Coupler | Swivel Grease Gun Coupler |

|---|---|---|

| Ease of Use | Less flexible, requires direct alignment | More flexible, adapts to angles easily |

| Applications | Ideal for fixed positions, less movement | Great for hard-to-reach areas and moving parts |

| Durability | Generally more durable due to simplicity | May wear out faster due to moving parts |

| Price Range | Generally lower cost | Typically higher cost due to design |

| Maintenance | Lower maintenance required | May require regular lubrication |

Selecting the right grease gun end for your machinery is essential for ensuring optimal performance and longevity of your equipment. When it comes to machinery maintenance, the grease application method can significantly affect how effectively lubricant reaches critical components. Different grease gun ends are designed to suit various applications, making it crucial to understand the distinctions to make an informed choice.

For instance, a needle nozzle end is ideal for precision lubrication in tight spaces, while a friction-ring coupler provides a secure connection for bulkier fittings. The selection process should also consider the type of machinery in use and its specific grease requirements. By choosing the correct grease gun end, you can enhance the lubrication process, reduce wear and tear, and ultimately minimize downtime associated with maintenance issues.

Understanding these factors not only aids in selecting the appropriate tool but also promotes a more efficient operation of your machinery.

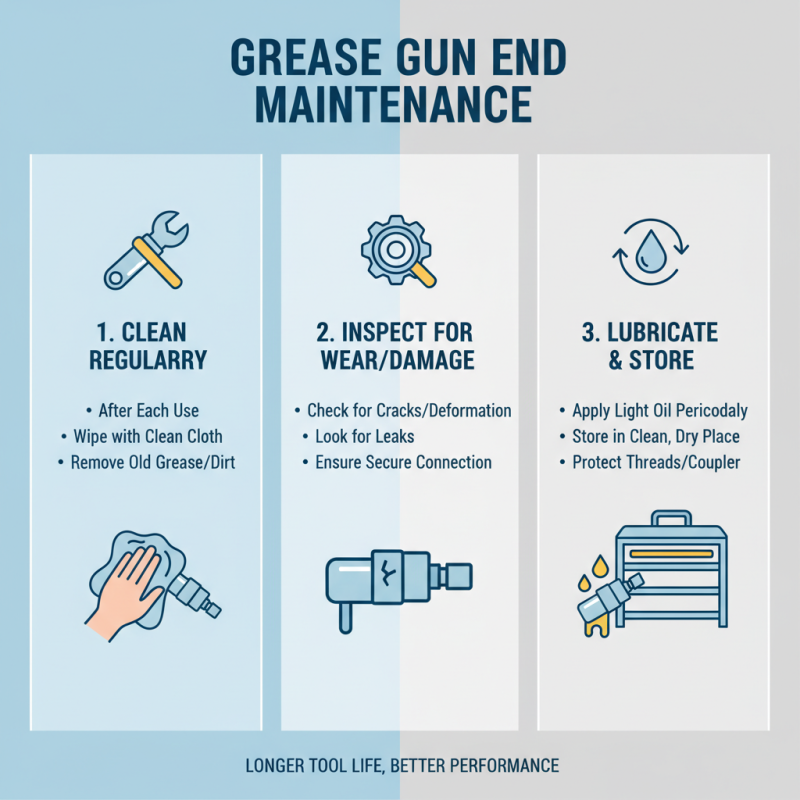

Maintaining grease gun ends and their accessories is crucial for the longevity and efficiency of your lubrication tools. One effective tip is to regularly clean the grease gun end after each use. This prevents the buildup of old grease and contaminants that can lead to clogging or malfunction. Simply wipe the end with a clean cloth and check for any signs of wear or damage, which can affect performance.

Another important maintenance practice is to inspect and replace seals and fittings as needed. Over time, seals can wear out due to constant pressure and usage, leading to leaks. Regular inspection allows for early detection of wear and timely replacement, ensuring that your grease gun operates smoothly and efficiently. Additionally, lubricating the moving parts of the grease gun can help maintain optimal functionality, reducing friction and wear and extending the life of the tool. By following these maintenance tips, you can keep your grease gun ends in excellent condition and ensure reliable performance when you need it most.