In the evolving landscape of industrial maintenance, the efficiency and reliability of equipment heavily depend on the effectiveness of lubrication systems. A crucial component in this arena is "grease line tubing and fittings," which serves as the conduit for delivering grease to various mechanical systems. According to a recent report by the International Association of Framework Engineers, approximately 30% of machinery failures can be traced back to inadequate lubrication practices, underscoring the need for high-quality tubing and fittings.

Industry expert Dr. Mark Reynolds, a leading authority on lubrication systems, emphasizes the importance of these components, stating, "The integrity of grease line tubing and fittings can make or break a lubrication system's performance." His insights resonate with many professionals who understand that the proper selection and maintenance of these fittings are vital to ensure optimal operation and prolonging the lifespan of machinery. As we delve into the top questions surrounding grease line tubing and fittings, it becomes clear that understanding their specifications, materials, and installation requirements is paramount for maintaining efficiency in industrial applications.

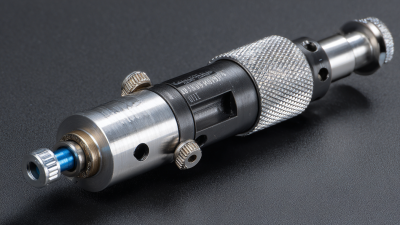

Grease line tubing plays a critical role in various industrial applications, ensuring efficient lubrication of machinery and equipment. Understanding the types and specifications of grease line tubing is vital for selecting the right solution for your operational needs.

Typically, grease line tubing is made from materials like polyurethane, nylon, or rubber, each exhibiting different levels of flexibility, temperature resistance, and pressure ratings.

For instance, polyurethane tubing is favored for its durability and resistance to abrasion, making it ideal for high-pressure applications, while nylon tubing is often chosen for its lightweight nature and good chemical resistance.

In terms of specifications, grease line tubing is usually classified based on its diameter and wall thickness. According to industry research, the most commonly used diameters range from 1/8 inch to 1/4 inch, catering to various lubrication systems. The pressure ratings for these tubes can often withstand between 300 to 2,000 psi, depending on the material and manufacturing processes utilized.

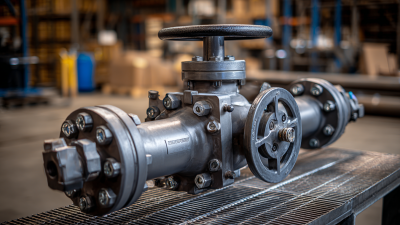

Additionally, proper fitting selection is crucial, as it must align with the tubing's specifications to prevent leaks and ensure the optimal flow of grease. Properly configured grease line systems can lead to a significant reduction in machinery downtime, as they contribute to consistent lubrication and ultimately enhance equipment lifespan and performance.

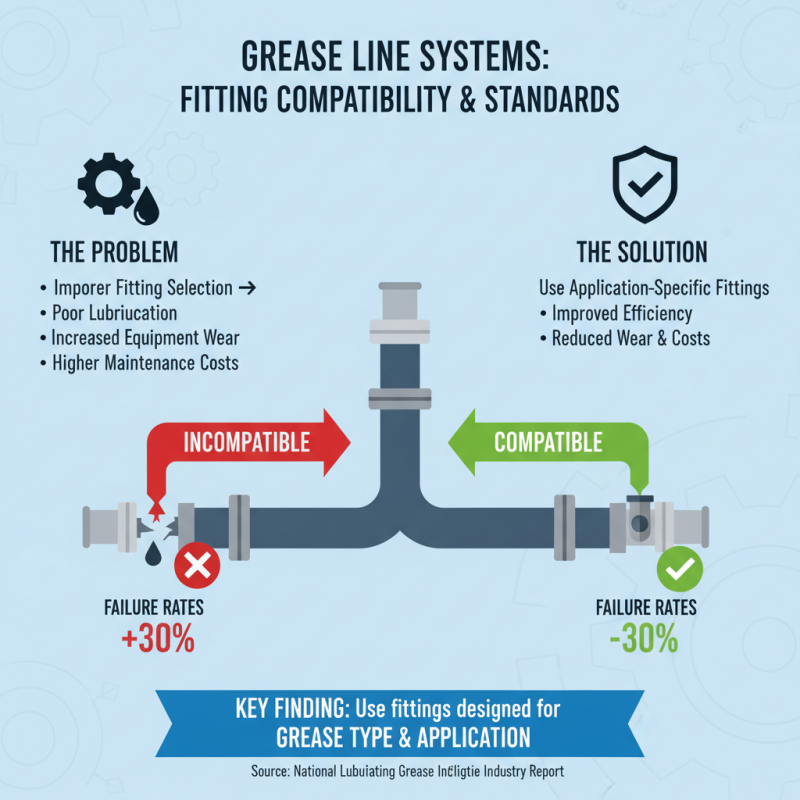

When considering grease line systems, understanding the compatibility and standards of key fittings is crucial for ensuring optimal performance and longevity. According to a recent industry report by the National Lubricating Grease Institute, improper fitting selection can lead to compromised lubrication efficiency, contributing to equipment wear and higher maintenance costs. The report highlights that the failure rates of grease line installations can be reduced by more than 30% when using fittings designed specifically for the type of grease and application involved.

Compatibility between fittings and grease line tubing is also essential. The American National Standards Institute (ANSI) guidelines dictate specific metrics for pressure ratings and temperature tolerances, emphasizing that fittings must match the characteristics of the grease being used. For instance, high-temperature greases require fittings made from materials that can withstand elevated temperatures without deforming, while also retaining their sealing capabilities. Furthermore, the proliferation of standardized sizes, such as those outlined in ISO 8434, has made it easier for engineers and maintenance technicians to select appropriate fittings that reduce the risk of leaks and improve overall system reliability.

Incorporating industry-standard fittings not only enhances operational efficiency but also ensures that maintenance schedules can be streamlined. The Society of Tribologists and Lubrication Engineers (STLE) found that organizations adopting standardized fittings experienced a significant reduction in downtime by up to 20%, primarily due to fewer necessary repairs. Given these considerations, investing in proper fittings for grease line systems is not just a matter of compliance; it is a critical factor in maintaining the operational integrity of machinery.

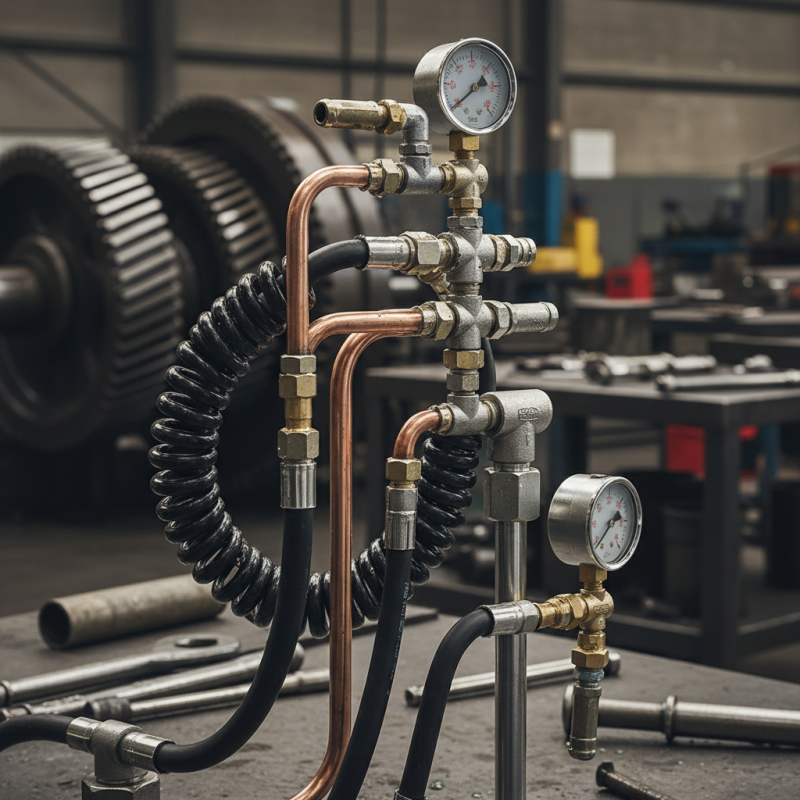

Proper sizing of grease line tubing is crucial for maintaining efficiency in lubrication systems. The diameter of the tubing directly affects the flow rate of grease. If the tubing is too narrow, it can restrict the flow, leading to inadequate lubrication of machinery components. This can result in increased wear and tear, leading to potential equipment failure and costly downtime. On the other hand, tubing that is too large may not provide the necessary pressure needed for effective distribution through the system.

Additionally, the length of the grease line also plays a significant role in performance. Longer lines can introduce friction, which may further reduce flow efficiency. It is essential to consider not only the diameter but also the overall length and configuration of the tubing to ensure optimal delivery of grease to the required points. Ensuring proper sizing and installation of fittings will help create a reliable pathway for grease, enhancing the performance and longevity of machinery. By addressing these factors, organizations can achieve greater operational efficiency and reduce maintenance costs associated with improperly lubricated systems.

| Dimension | Typical Size (inches) | Max Working Pressure (psi) | Material | Common Applications |

|---|---|---|---|---|

| Inner Diameter | 0.187 | 3,500 | Steel | Automotive applications |

| Outer Diameter | 0.250 | 2,500 | Stainless Steel | Industrial machinery |

| Length | 10.0 | 1,500 | Polyethylene | Agricultural equipment |

| Fitting Type | 1/4 NPT | 5,000 | Brass | Lubrication systems |

| Hose Type | Flexible | 2,000 | Rubber | Heavy-duty machinery |

Maintaining grease line fittings is crucial for ensuring optimal performance and longevity in mechanical systems. Regular inspection is the first step in effective maintenance, allowing for the early detection of wear, leaks, or blockages that could compromise the functionality of the grease delivery system. Technicians should be trained to recognize signs of wear, such as cracks or deformation in fittings, and to assess the condition of the tubing connected to them. This proactive approach can prevent more extensive repairs and downtime in the future.

Cleaning grease line fittings regularly is another essential practice. Accumulated grease can lead to clogs and reduce the efficiency of lubrication. Using appropriate cleaning agents and tools will help maintain the surfaces of the fittings, ensuring a smooth flow of grease. Additionally, checking and replacing seals and gaskets as needed can prevent leaks and maintain the integrity of the entire system. By following these best practices, operators can enhance the reliability and efficiency of their grease line systems, ultimately leading to improved equipment performance and reduced maintenance costs.

When dealing with grease line tubing and fittings, understanding industry regulations is paramount for ensuring safety and operational efficiency. Various organizations set standards that govern the materials and designs used in grease line systems, addressing factors like pressure ratings, temperature tolerances, and compatibility with different lubricants.

Compliance with these regulations not only bolsters safety but also enhances the longevity and performance of the equipment. Regular audits and reviews of these standards help organizations keep up to date with any changes that may impact their operations.

Tips for navigating these regulations include staying informed about changes in industry guidelines, which can frequently occur due to technological advancements and evolving safety practices. Join industry associations or online forums that focus on lubrication systems, as they often provide valuable updates and resources. Additionally, implementing a robust training program for employees about regulatory compliance can minimize risks while promoting a culture of safety within the organization.

Monitoring and maintaining your grease line components also play a critical role in adherence to industry standards. Conduct regular inspections and testing to ensure all fittings and tubing are in ideal working condition and meet the necessary specifications. This proactive approach not only aids in compliance but also contributes to the overall efficiency of your lubrication system, ultimately benefiting your operations.