The use of a 4 inch gate valve can greatly enhance system efficiency. This component plays a crucial role in controlling fluid flow. Its design allows for quick on/off operation, making it ideal for many applications.

A 4 inch gate valve provides various benefits. It offers low pressure drop, making it energy efficient. Additionally, its robust construction ensures durability. Many industries, like water treatment and oil, rely on this valve type for its dependable performance.

However, not all 4 inch gate valves are created equal. Some may experience wear over time. Users must choose wisely, considering quality and application needs. Making informed decisions can lead to better system outcomes.

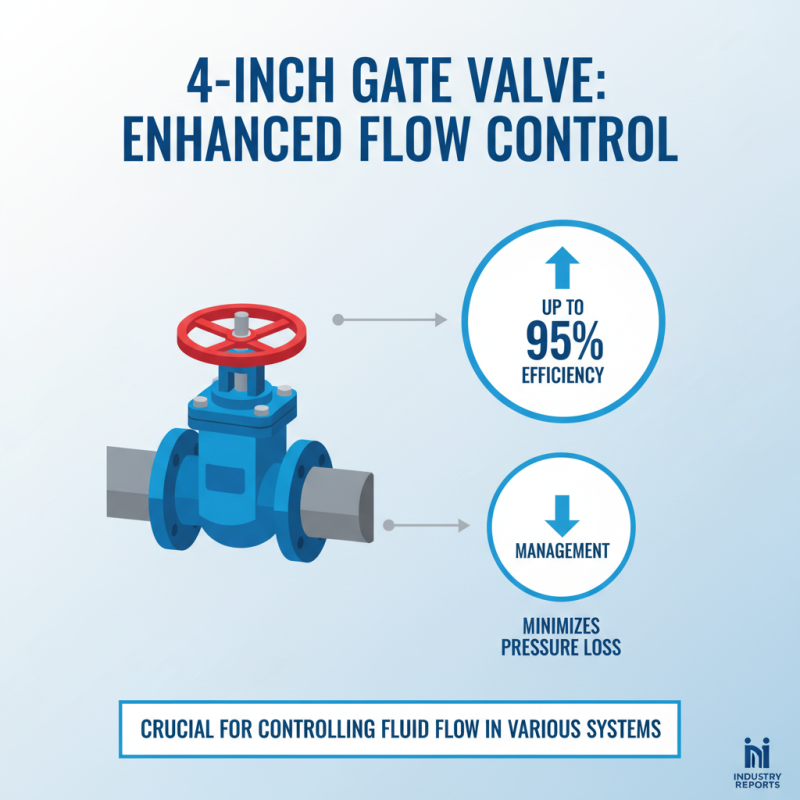

Gate valves are crucial for controlling fluid flow in various systems. A 4-inch gate valve offers enhanced flow control, making it an essential component. According to industry reports, these valves can provide up to 95% efficiency in flow management. This efficiency helps minimize pressure loss, leading to smoother operations within pipelines.

The design of a 4-inch gate valve allows for full bore flow, which means there is little to no restriction. This characteristic is especially beneficial in large-scale applications, where maintaining high flow rates is vital. In some scenarios, it's been noted that using a gate valve can result in a 30% reduction in energy consumption compared to other valve types. This statistic highlights the economic advantages of choosing the right valve for your system.

However, gate valves may not be universally perfect. They require proper maintenance to ensure longevity. If not regularly checked, they can develop issues that lead to increased friction. This can counteract the efficiencies they promise. Operators must be vigilant and proactive in maintaining these valves to fully reap the benefits.

In various industrial settings, the durability and longevity of 4-inch gate valves are paramount. According to a recent industry report, these valves typically have a lifespan of over 20 years when properly maintained. This longevity is often attributed to their robust construction. Made from materials like ductile iron or stainless steel, they withstand high pressure and corrosive fluids.

However, it’s important to acknowledge that not all installations ensure optimal performance. Some users report issues related to improper installation or lack of regular maintenance. For instance, an engineering study found that nearly 15% of gate valve failures were due to improper alignment. This shows the importance of skilled installation and routine checks.

Despite their advantages, the potential for leaks cannot be overlooked. A survey indicated that 5-10% of gate valves might develop leaks in older systems. High-quality seals and threading can mitigate these risks, but some systems may still face challenges. Understanding these factors is crucial for maximizing the lifespan of 4-inch gate valves in your operations.

When considering cost-effectiveness, 4-inch gate valves stand out in numerous applications. These valves offer reliable performance in various systems, reducing long-term maintenance costs. According to industry reports, proper valve selection can cut operational expenses by up to 30%. This makes gate valves an attractive option for those looking to optimize system efficiency.

Installation costs are another important factor. A 4-inch gate valve is relatively straightforward to install. It’s manageable for skilled technicians, potentially decreasing labor expenses. Some installations report up to a 20% reduction in initial setup costs when utilizing gate valves. However, choosing the wrong type can lead to inefficiencies and increased spending over time.

A major consideration is the lifetime value of these valves. Gate valves typically have a longer operational lifespan compared to other types. Many reports indicate that a well-maintained gate valve can last over 20 years. But without proper care, this lifespan can significantly shorten. Therefore, regular maintenance is critical, making it essential to weigh both initial costs and future upkeep needs.

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| High Flow Capacity | Allows for maximum flow of fluids when fully opened. | Reduces pumping costs by minimizing pressure drop. |

| Versatile Applications | Suitable for various types of fluids, including water, oil, and gas. | Provides a flexible solution for diverse system requirements. |

| Durability | Made from robust materials to withstand high pressure and temperature. | Long lifespan reduces replacement costs over time. |

| Ease of Use | Simple operation with manual or automated options available. | Lower labor costs for operation and maintenance. |

| Low Maintenance | Requires minimal upkeep due to its mechanical design. | Saves costs associated with frequent maintenance checks. |

| Reduced Leakage | Tight sealing reduces the risk of leaks when closed. | Prevents product losses and environmental hazards. |

| Compact Design | Space-efficient, making it ideal for limited installations. | Reduction in installation costs in cramped spaces. |

| Wide Range of Sizes | Available in various dimensions to suit different systems. | Flexibility to meet specific process requirements. |

| Cost-Effective Solution | Lower upfront and energy costs compared to other valves. | Overall savings in system operations and energy expenses. |

| High Reliability | Consistent performance with low failure rates. | Reduces unexpected costs from downtime or repairs. |

When it comes to gate valves, the 4-inch size stands out for its ease of maintenance and operation. The design typically allows for straightforward access to components, resulting in reduced downtime during repairs. Reports from industry experts show that regular maintenance can increase valve lifespan by up to 30%. This statistic highlights the importance of choosing user-friendly products.

With various systems in place, operators should understand the nuances of maintaining gate valves. For instance, lubricating the stem should be done according to the manufacturer's guidelines. Proper lubrication prevents corrosion and seizing, which are common issues.

Tip: Always check for visual leaks during regular inspections.

Another aspect is the operation of 4-inch gate valves. They usually operate with a simple turn of the wheel or lever. This reduces operator fatigue and ensures quick adjustments in flow control. According to recent data, clearer operation procedures can enhance system efficiency by 15%.

Tip: Keep a checklist for regular maintenance tasks.

Neglecting these practices can lead to inefficient operations. Operators must remain aware of their system's specifications. Small oversights can lead to major issues in the long run. Regular training can equip staff with the necessary knowledge to manage and operate valves effectively.

The versatility of 4 inch gate valves makes them ideal for various applications. They are commonly used in water supply systems, irrigation, and even industrial processes. Their ability to provide a tight seal allows them to control the flow effectively. This makes them a go-to choice in situations where leakage must be minimized.

In residential systems, these valves can manage hot and cold water lines. They can handle different types of fluids, enhancing their adaptability. However, their performance can sometimes be compromised by debris or sediment in the fluid. This can lead to blockages and require regular maintenance. While they are durable, the environment they operate in can affect their longevity.

Using a 4 inch gate valve offers practicality but has its drawbacks. Ensuring they are installed correctly is crucial. A poorly installed valve can lead to significant issues down the line. Regular inspections are essential to guarantee they function optimally. The balance between their widespread use and the need for upkeep can pose challenges. It's an aspect worth considering when integrating them into your system.