In the automotive industry, the quest for enhanced vehicle performance and longevity has led many to discover the advantages of moly lube. Renowned expert in lubrication technology, Dr. James Hargrove, emphasizes the significance of this innovative lubricant, stating, "Moly lube stands out as a game-changer, providing superior protection and efficiency for various automotive applications." As we look toward the future of vehicle maintenance, understanding the top moly lube applications and their benefits becomes paramount.

Moly lube, distinguished by its unique composition, has garnered attention for its ability to reduce friction, protect against wear, and improve overall engine performance. From high-performance engines to everyday vehicles, the applications of moly lube are vast and varied, making it a valuable asset for both amateur mechanics and professional technicians alike. As we explore the myriad ways in which moly lube can enhance vehicle efficiency and durability, it is essential to recognize its importance in the ever-evolving landscape of automotive care. In 2025 and beyond, the role of moly lube will undoubtedly continue to expand, solidifying its place as a cornerstone of modern automotive maintenance.

Molybdenum disulfide, commonly known as moly lube, is a unique and highly effective lubricant recognized for its exceptional properties. It is a solid lubricant that is often used in high-load and high-temperature applications due to its ability to withstand extreme conditions without compromising performance. Its layered structure allows it to shear easily, providing lubricating qualities that reduce friction between surfaces, minimize wear, and enhance the overall lifespan of engine components.

One of the key benefits of moly lube is its excellent adhesion to metal surfaces, ensuring a consistent lubricant film even under severe conditions. This makes it particularly suitable for various automotive applications, including engine assemblies, gears, and bearings. Additionally, moly disulfide has a remarkable resistance to oxidation and thermal degradation, which means that it can maintain its effectiveness over prolonged periods without significant breakdown.

By utilizing moly lube, vehicle owners can experience improved efficiency, reduced energy consumption, and ultimately better performance from their vehicles, contributing to a smoother driving experience and prolonged mechanical integrity.

Molybdenum disulfide, commonly known as moly lube, is increasingly becoming a key component in automotive maintenance and repair due to its unique lubrication properties and ability to withstand extreme conditions. One of the primary applications of moly lube is in engine assembly and lubrication, where it forms a protective layer that reduces metal-to-metal contact. According to a report by the Lubricating Grease Institute, moly lube can enhance wear resistance by up to 40%, making it invaluable for vehicles that operate under high loads and temperatures.

Another significant application lies in the treatment of drivetrain components such as differentials and manual transmissions. Moly lube's high lubricity ensures smoother operation and minimizes friction, ultimately increasing the lifespan of these critical parts. Research conducted by the Society of Automotive Engineers indicates that vehicles utilizing moly-based lubricants in their drivetrains show a 20% improvement in fuel efficiency over those using conventional fluids. This not only reduces operational costs for vehicle owners but also contributes positively to overall vehicle performance.

Additionally, moly lube can be highly beneficial in reducing the need for frequent maintenance and repair. Its capacity to reduce wear translates into fewer breakdowns and lower overall maintenance costs. The American Petroleum Institute has noted that incorporating moly lube into routine service schedules can lead to a marked decrease in repair instances, further justifying its importance in the automotive industry.

Moly Lube is increasingly recognized for its ability to enhance engine performance and extend the operational lifespan of vehicles. The incorporation of molybdenum disulfide in lubricant formulations creates a unique protective barrier that reduces friction between engine components. This significant decrease in friction leads to increased efficiency, allowing engines to operate at optimal temperatures while minimizing wear. As a result, vehicles experience improved performance, particularly during high-stress applications such as towing or heavy acceleration.

In addition to improving efficiency, using Moly Lube contributes to the longevity of critical engine parts. With its exceptional load-bearing characteristics, Moly Lube forms a durable layer on surfaces, protecting them from the abrasive effects that can cause premature degradation. This is especially important for high-performance engines, where the demands placed on the components are substantially greater.

By mitigating wear and tear, Moly Lube helps maintain engine integrity over time, potentially leading to lower maintenance costs and extending the intervals between oil changes. Overall, the benefits of Moly Lube make it a valuable choice for those seeking both enhanced performance and longer-lasting vehicles.

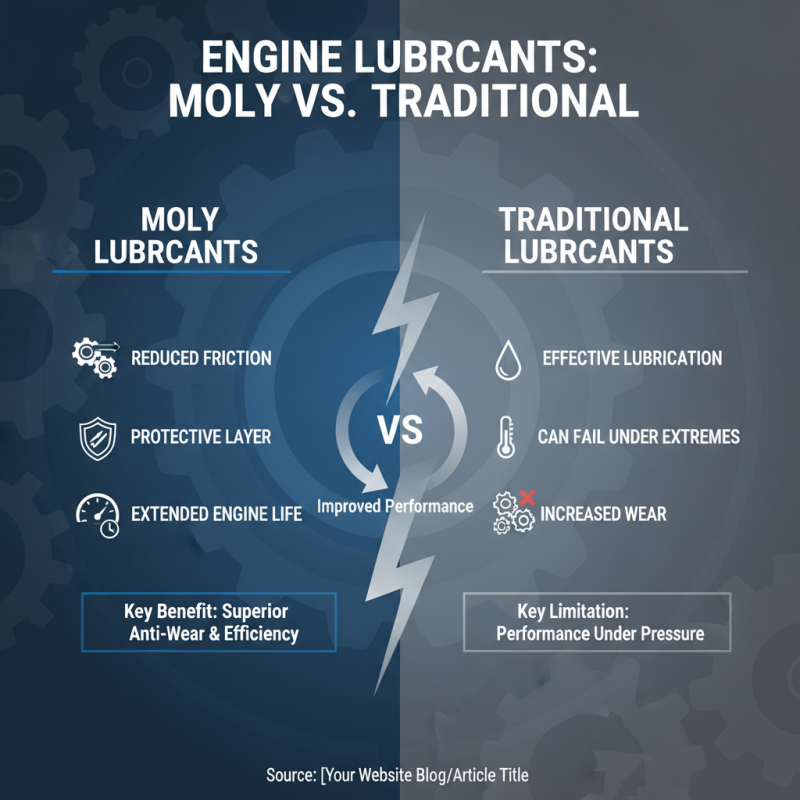

When evaluating the performance of molybdenum disulfide (moly) lubricants versus traditional lubricants, it's essential to focus on their respective mechanisms and effects on vehicle engines. Moly lubes are known for their ability to reduce friction significantly, thanks to their unique ability to adhere to metal surfaces and create a protective layer. This results in reduced wear and tear on engine components, thereby extending the lifespan of the engine and improving overall efficiency. In contrast, traditional lubricants may provide effective lubrication but can sometimes fail to maintain performance under extreme pressures or temperatures, leading to increased friction and wear.

Another critical aspect to consider in the comparative analysis is the thermal stability and resistance to breakdown of both types of lubricants. Moly lubricants tend to perform better in high-heat environments, where they maintain their protective properties without degrading. This stability leads to better engine performance, especially in demanding conditions. Traditional lubricants may rely on additives to enhance their properties, which can wear out over time, resulting in the need for more frequent changes and potential engine damage. Ultimately, while both moly lubes and traditional lubricants serve the purpose of reducing friction and wear, moly lubricants offer superior long-term benefits and protection for modern vehicles.

As we look toward 2025, the landscape of moly lube technology is set to undergo significant advancements that promise to enhance vehicle performance. The integration of advanced molybdenum disulfide (moly) lubricants is being increasingly recognized for their ability to reduce friction, minimize wear, and improve overall efficiency in engines and mechanical systems. According to industry reports, moly lubricants can reduce engine wear by up to 30% while increasing fuel efficiency by approximately 5-10%. These improvements are driving the adoption of moly-based formulations across a range of vehicle types, from passenger cars to heavy-duty trucks.

Future trends indicate a shift toward more environmentally friendly formulations that maintain high performance levels. The development of synthetic moly lubricants is expected to significantly reduce harmful emissions. Innovations in nano-technology are also emerging, allowing for the creation of lubricants with enhanced properties at the molecular level. This progress not only benefits vehicle longevity but also contributes to sustainability efforts within the automotive industry.

Tips: When selecting a lubricating product for your vehicle, consider opting for synthetic formulations that feature robust moly content. Additionally, regular maintenance and timely lubricant changes can maximize the benefits of these advanced products, ensuring optimal performance and efficiency over time. Always consult your vehicle’s manual for compatibility to achieve the best results.

| Moly Lube Application | Key Benefits | Future Trends |

|---|---|---|

| Engine Lubrication | Enhanced wear protection and reduced friction | Integration with smart sensors for real-time monitoring |

| Transmission Fluid | Improved shifting performance and lower operating temperatures | Development of eco-friendly formulations |

| Chassis Grease | Increased lifespan of components and reduced maintenance frequency | Use of nanotechnology for enhanced protection |

| Brake Lubricants | Noise reduction and improved braking efficiency | Focus on high-performance environments and electric vehicles |

| Differential Lubrication | Smooth operation under high load conditions | Adaptation to hybrid systems and advanced coatings |